Industry information

Company News

- Imitation wood grain aluminum veneer: retro style of modern architecture

- Aluminum veneer curtain wall, the fashionable coat of architecture

- Aluminum veneer customization, creating a new trend of personalized space

- Wood grain aluminum veneer: the fashionable choice for modern architecture?

- Imitation wood grain aluminum veneer: a retro choice for modern architecture

Industry dynamics

- What is the color and texture of aluminum veneer?

- How to optimize the installation time of aluminum veneer?

- Aluminum veneer customization: an artistic journey to create personalized spaces

- Does the density of holes in punched aluminum veneer affect sound transmission?

- Wood grain aluminum veneer: a perfect fusion of natural texture and metallic texture

Frequently asked questions

- How does aluminum veneer provide the wind resistance required for modern buildings?

- Will the thickness of aluminum veneer affect its service life?

- What are the limitations of the application scope of aluminum veneer?

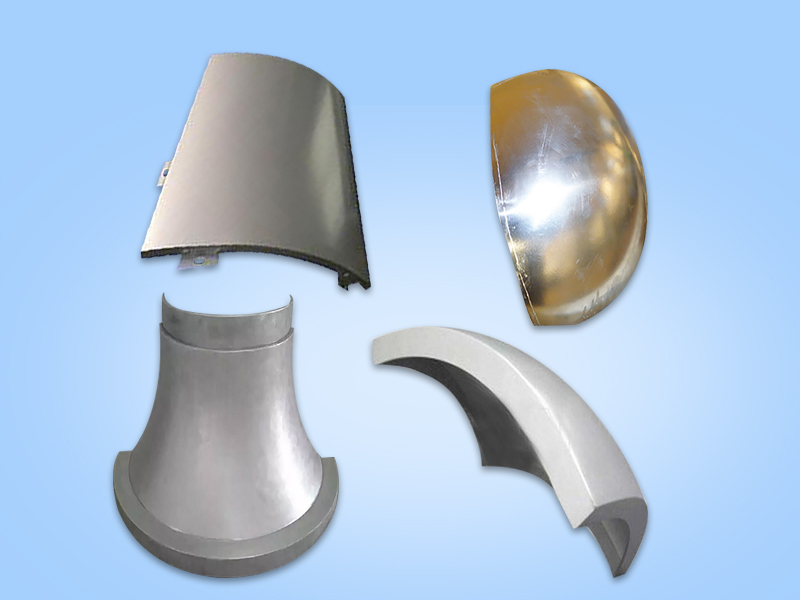

- What are the types of aluminum veneer?

- Does the production of aluminum veneer require certification?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

What is the corrosion resistance of aluminum veneer under rainwater erosion?

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: 2022-03-04 12:52:49

- Click:0

Aluminum veneerIt is a common building material, and its corrosion resistance under rainwater erosion has a significant impact on the service life and aesthetics of buildings. Below, we will provide a detailed introduction to the corrosion resistance of aluminum veneer under rainwater erosion.

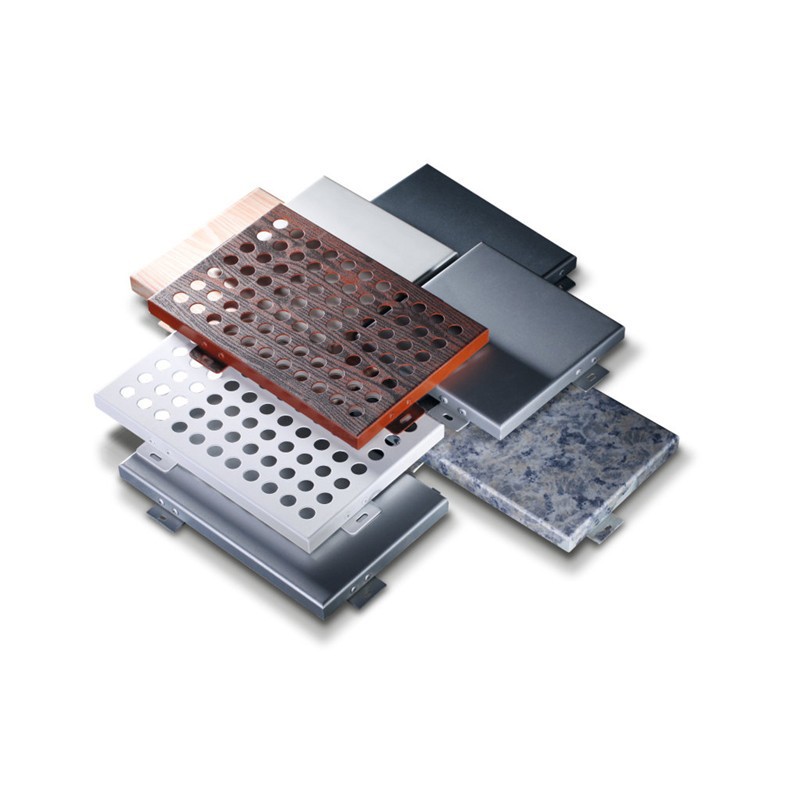

1. Material characteristics

The main raw material for aluminum veneer is aluminum magnesium alloy, which has good corrosion resistance. Aluminum magnesium alloy is prone to form a dense oxide film in air, which can effectively protect the surface of aluminum veneer from corrosion. Aluminum veneer also has good acid alkali and salt alkali resistance, and can maintain surface stability in acidic or alkaline environments.

1. Surface treatment

The surface treatment of aluminum veneer also has a certain impact on its corrosion resistance. Common surface treatment methods include anodizing, spraying, and electrophoretic coating. Anodizing treatment can form a dense oxide film, which can effectively improve the corrosion resistance and hardness of aluminum veneer, while also increasing its aesthetic appeal.

1. Corrosion resistance performance

According to the national standard GB/T8624-2012 "Classification Method for Combustion Performance of Building Materials", the fire rating of aluminum veneer is divided into four levels: A1, A2, B1, B2, and C. A1 level is the highest level, indicating that aluminum veneer has excellent corrosion resistance and can withstand long-term corrosion in acidic or alkaline environments; B1 level is a medium level, indicating that aluminum veneer has good corrosion resistance, but may be corroded in acidic or alkaline environments; B2 and C grades are lower grades, indicating poor corrosion resistance of aluminum veneer.

Aluminum veneer has good corrosion resistance under rainwater erosion. By selecting appropriate materials and surface treatment methods, the corrosion resistance of aluminum veneer can be further improved, ensuring the safety and stability of buildings. When using aluminum veneer, corresponding materials and surface treatment methods should be selected according to actual needs, and necessary measures should be taken for waterproofing and anti-corrosion treatment.

Customer service QQ

Customer service QQ