Industry information

Company News

- Wood grain aluminum veneer: a perfect fusion of nature and modernity

- Wood grain aluminum veneer, a modern interpretation of natural textures

- The fashionable charm of wood grain aluminum veneer: a green choice for modern architecture

- Aluminum veneer: lightweight building material, shaping the beauty of modern space

- New trend of aluminum veneer: light luxury texture, new choice for home life

Industry dynamics

- Aluminum veneer: the beauty of architecture, simplicity is not simple

- Aluminum veneer: providing multiple material options for buildings

- Aluminum veneer: the fashionable choice of modern architecture, revealing its unique charm!

- The fashion transformation of aluminum veneer curtain wall separated by one board

- Separated by a board, aluminum veneer curtain wall interprets modern architectural aesthetics

Frequently asked questions

- What are the types of aluminum veneer?

- What are the limitations of the application scope of aluminum veneer?

- Will the thickness of aluminum veneer affect its service life?

- Is the surface treatment method of aluminum veneer restricted?

- Does the production of aluminum veneer require certification?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

How to optimize the installation time of aluminum veneer?

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: 2022-03-08 11:38:54

- Click:0

Aluminum veneerThe installation time is one of the key factors affecting the efficiency and quality of building construction. Below, we will provide a detailed introduction on how to optimize the installation time of aluminum veneer.

1. Advance planning

Before installing aluminum veneer, sufficient planning work is required. This includes determining the installation location, quantity, shape, etc., as well as developing a detailed installation plan and schedule. By planning ahead, unnecessary delays and errors can be avoided during the actual installation process, thereby improving installation efficiency and quality.

1. Reasonably arrange personnel and equipment

The installation of aluminum veneer requires a significant amount of manpower and equipment support. When arranging personnel and equipment, factors such as quantity, quality, and coordination need to be considered to ensure the smooth progress of the installation process. Training and debugging of personnel and equipment are also needed to improve their operational skills and adaptability.

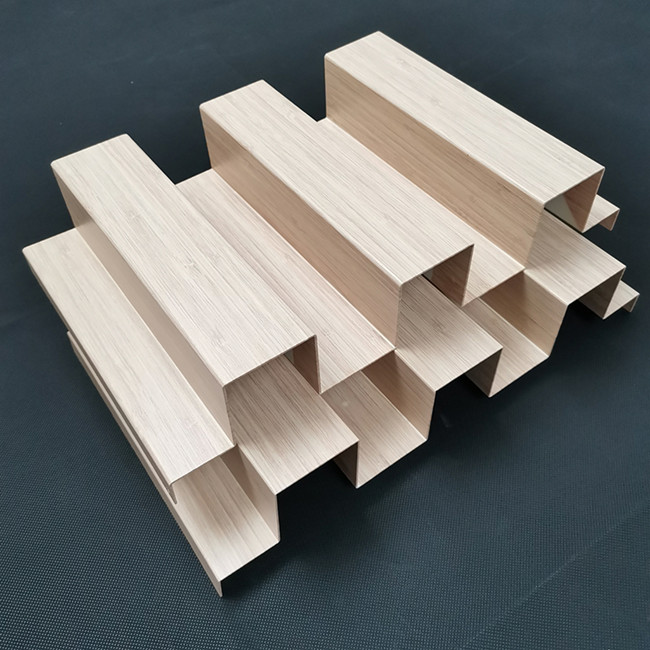

1. Use prefabricated components

Prefabricated parts are pre made aluminum veneer components that can be quickly assembled and installed on site. Compared to on-site cutting and processing, using prefabricated components can greatly shorten the installation time of aluminum veneer and reduce errors and waste. In practical applications, prefabricated components should be used as much as possible to optimize the installation time of aluminum veneer.

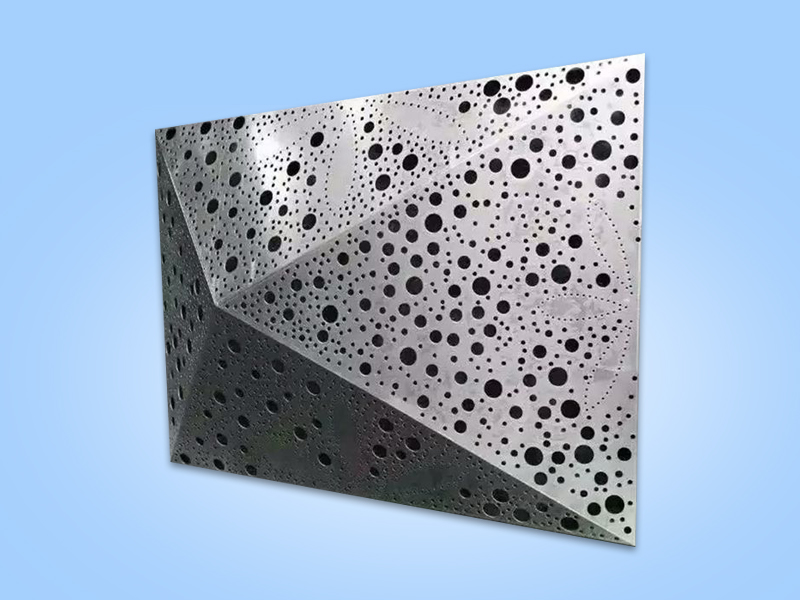

1. Reasonably arrange the process

The installation of aluminum veneer usually involves multiple processes, such as measurement, cutting, punching, fixing, etc. In order to optimize installation time, it is necessary to arrange the sequence and time of these processes reasonably to avoid duplication or overlap. It is also necessary to adjust the difficulty and complexity of the process according to the actual situation to ensure the safety and stability of the installation process.

The installation time of aluminum veneer is one of the important factors affecting the efficiency and quality of construction. By planning in advance, arranging personnel and equipment reasonably, using prefabricated parts, and arranging processes reasonably, the installation time of aluminum veneer can be effectively optimized, and construction efficiency and quality can be improved. It can also reduce errors and waste, lower costs and risks, and provide users with more reliable and efficient products and services.

Customer service QQ

Customer service QQ