Industry information

Company News

- Wood grain aluminum veneer: natural charm in modern architecture

- Aluminum veneer curtain wall, the 'gorgeous coat' of modern architecture

- Aluminum veneer curtain wall, the fashionable coat of architecture

- Wood grain aluminum veneer, the "hidden charm" of modern architecture

- Aluminum veneer: the "green warrior" of modern architecture

Industry dynamics

- Aluminum veneer price - control and management of procurement costs

- Aluminum veneer: the fashionable choice of modern architecture, revealing its charm

- Aluminum veneer: providing multiple material options for buildings

- Imitation wood grain aluminum veneer: a fashionable choice for modern architecture

- Colorful hollow aluminum veneer creates a flowing picture of fashionable architecture

Frequently asked questions

- What are the limitations of the application scope of aluminum veneer?

- Is the surface treatment method of aluminum veneer restricted?

- Does the production of aluminum veneer require certification?

- Can the insulation function of aluminum veneer improve the comfort of buildings?

- How does aluminum veneer provide the wind resistance required for modern buildings?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Does the density of holes in punched aluminum veneer affect sound transmission?

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: February 21, 2025 06:12:29

- Click:0

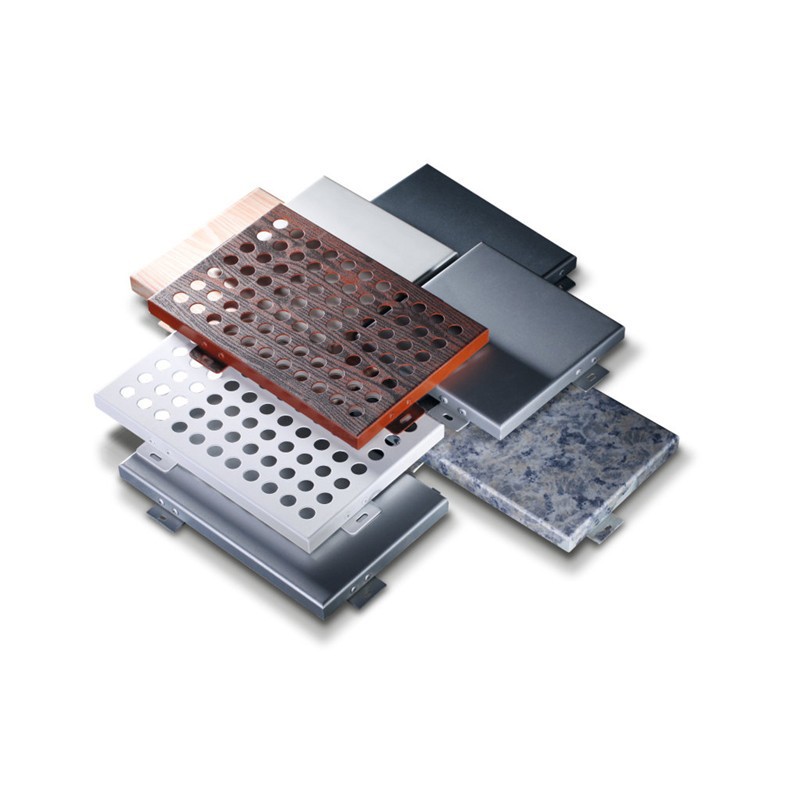

In the field of architecture,Aluminum veneerGradually becoming a highly anticipated new material. Compared to traditional exterior wall decoration materials, aluminum veneer has better breathability and transparency, which can bring a more unique and personalized appearance to buildings. Punched aluminum veneer is a common type of aluminum veneer, and its hole density also affects its impact on sound transmission. Below is a detailed introduction to the influence of hole density on sound transmission in perforated aluminum veneer.

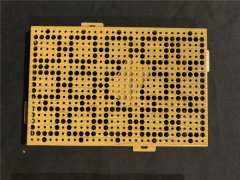

1、 Pore density and sound conduction

Generally speaking, the higher the density of holes in perforated aluminum veneers, the weaker their ability to transmit sound. This is because holes form air barriers, causing reflection, refraction, and other phenomena during the propagation of sound waves, thereby reducing the efficiency of sound wave propagation. Holes are also prone to accumulating dust and dirt, which can affect their appearance and service life.

2、 Hole density and noise isolation

In contrast, perforated aluminum veneer with lower hole density has better noise isolation effect. This is because low-density pores can form fewer air barriers, making it easier for sound waves to penetrate aluminum veneers, thereby improving the propagation efficiency of sound waves. Low density pores can also reduce the resonance effect on the surface of aluminum veneer, thereby further reducing the generation of noise.

3、 The influence of other factors

In addition to pore density, there are other factors that can also affect the impact of perforated aluminum veneer on sound transmission. For example, the thickness and material of aluminum veneer can affect its resistance to sound. When selecting perforated aluminum veneer, it is necessary to choose according to actual needs.

4、 Selection of application scenarios

In practical applications, it is also necessary to select perforated aluminum veneers with different hole densities according to different scenarios. For example, in environments with high noise levels, aluminum veneers with higher hole density can be selected for isolation; In places that require good lighting, aluminum veneers with lower hole density can be chosen for design.

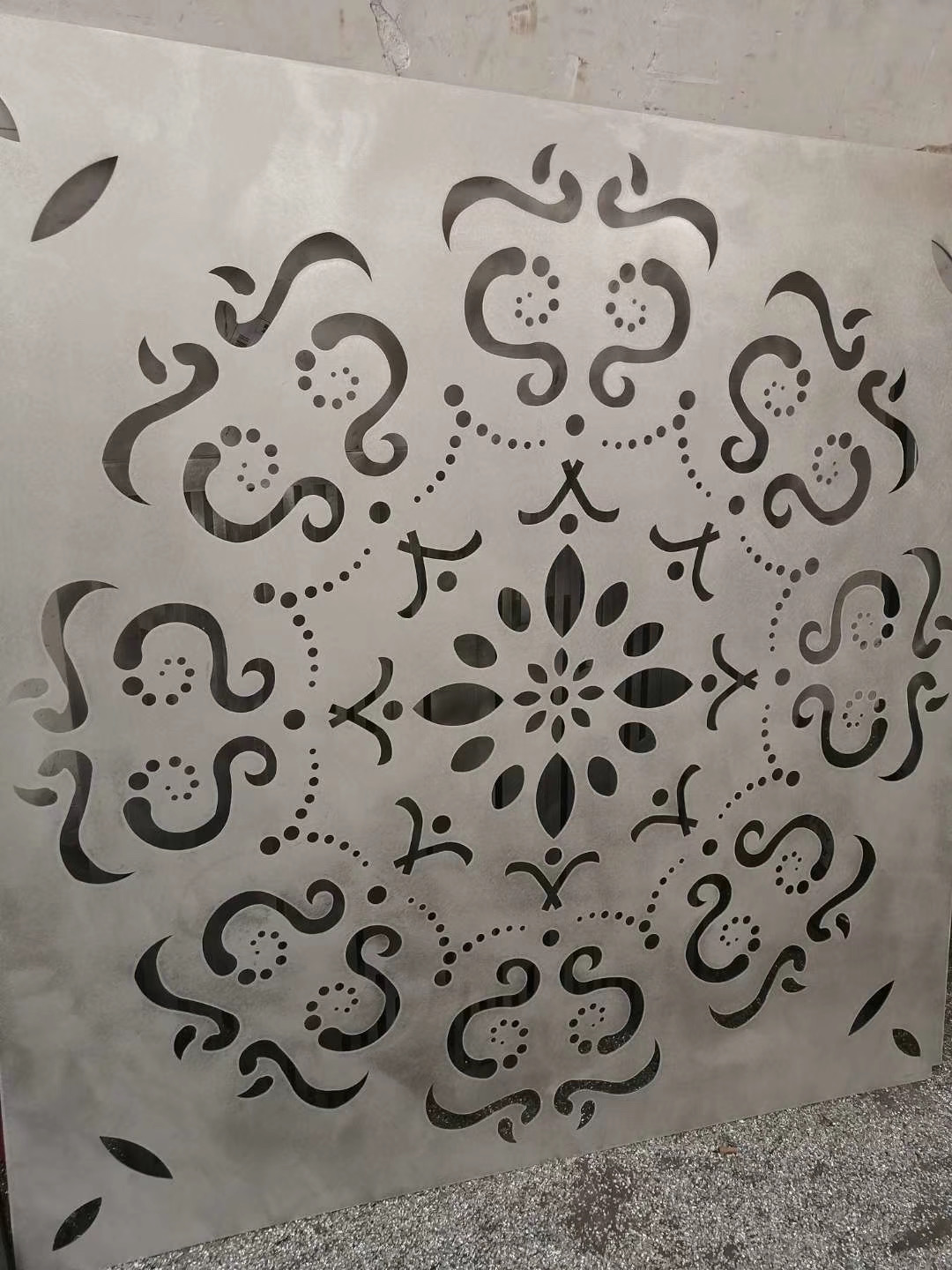

The density of holes in punched aluminum veneer directly affects its impact on sound transmission. Through scientific manufacturing processes and material properties, as well as correct application and maintenance methods, the advantages of perforated aluminum veneer can be fully utilized to bring a more unique and personalized appearance to buildings, while also contributing to environmental protection.

Customer service QQ

Customer service QQ