Industry information

Company News

- Aluminum veneer: the secret behind its lightweight design

- Wood grain aluminum veneer: a perfect fusion of nature and modernity

- Aluminum veneer: the fashionable outerwear of modern architecture

- Customized aluminum veneer, creating a new proposition for personalized space!

- Aluminum veneer: Behind the lightweight, the secret journey of aluminum

Industry dynamics

- Creating a signature modern architectural style with 3mm painted aluminum veneer

- Wood grain aluminum veneer: the "beauty responsibility" of the aluminum industry

- How to choose suitable perforated aluminum veneer products for construction?

- Unveiling Wood Grain Aluminum Veneer: The 'Master of Disguise' in Fashion Building Materials

- Aluminum veneer: a shining pearl in modern architecture

Frequently asked questions

- How to evaluate the impact of the plasticity of aluminum veneer on the appearance of buildings?

- What are the types of aluminum veneer?

- Will the thickness of aluminum veneer affect its service life?

- How does aluminum veneer provide the wind resistance required for modern buildings?

- Does the production of aluminum veneer require certification?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Oxidation treatment process and surface effect of aluminum veneer

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: March 17, 2025 00:33:38

- Click:0

Aluminum veneerAs a lightweight and high-strength building material, it has excellent processing performance and decorative effect. The oxidation treatment process on the surface of aluminum veneer is one of the key factors affecting its surface effect. The following will provide a detailed introduction to the oxidation treatment process and surface effect of aluminum veneer.

1、 Oxidation treatment process

The oxidation treatment process of aluminum veneer is mainly divided into two types: anodic oxidation and cathodic oxidation. Anodizing is the electrolytic oxidation treatment of aluminum veneer as an anode, which forms a dense oxide film on its surface, thereby improving its hardness and wear resistance, and making it have better anti fouling and durability. Cathodic oxidation is the electrolytic reduction treatment of aluminum veneer as a cathode, forming a metal protective film on its surface to improve its corrosion resistance and oxidation resistance.

2、 Surface effect

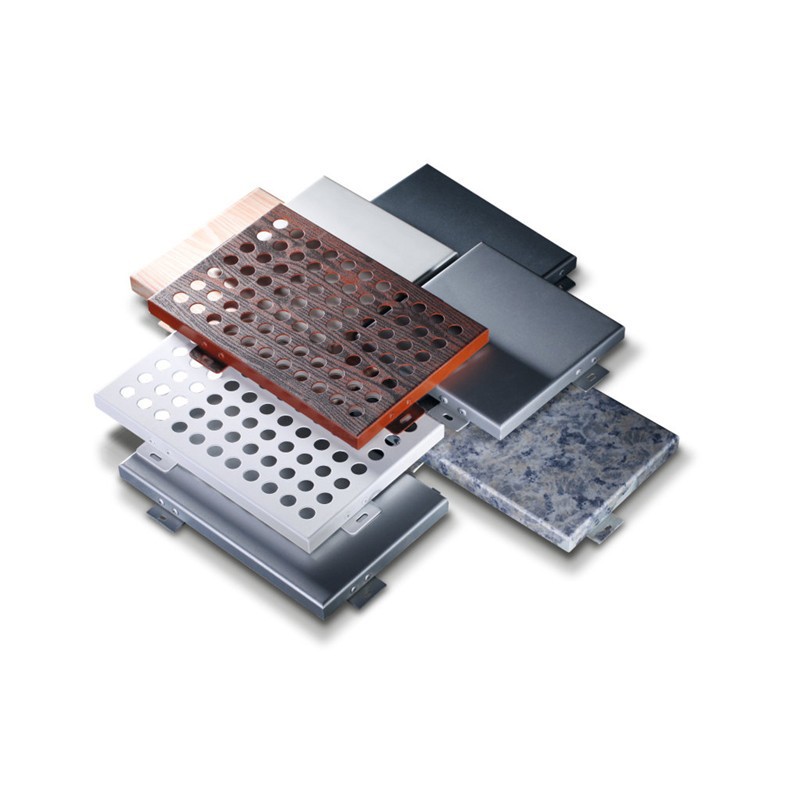

The surface of aluminum veneer after oxidation treatment exhibits different effects. Generally speaking, the surface of aluminum veneer after oxidation treatment will form a uniform and dense oxide film, which improves its hardness and wear resistance, as well as better anti fouling and durability. The surface of aluminum veneer after oxidation treatment can also exhibit different colors and texture effects, such as gold, silver, black, white, as well as texture effects such as frosted, brushed, and mirror finish. These different surface effects can provide richer choices for the application of aluminum veneer.

3、 Application Fields

After oxidation treatment, aluminum veneer has excellent decorative effect and anti-corrosion performance, and is widely used in fields such as building exterior wall decoration, roof greening, urban furniture, etc. In terms of exterior wall decoration, aluminum veneer treated with oxidation can present different colors and texture effects, thereby adding a more unique and fashionable appearance to the building. In terms of roof greening, the oxidized aluminum veneer has a smooth and flat surface, which is not easy to accumulate dust and dirt, and can effectively protect the growth environment of vegetation. In terms of urban furniture, aluminum veneer treated with oxidation can be used to create various shapes and patterns of city seats, trash cans, and other facilities. It not only has a beautiful appearance, but also provides a more comfortable user experience.

The oxidation treatment process of aluminum veneer has a significant impact on its surface effect. After oxidation treatment, the surface of aluminum veneer presents a uniform and dense oxide film, which has better hardness and wear resistance, and can also present different color and texture effects. These characteristics make aluminum veneer widely used in fields such as exterior wall decoration, roof greening, and urban furniture.

Customer service QQ

Customer service QQ