Industry information

Company News

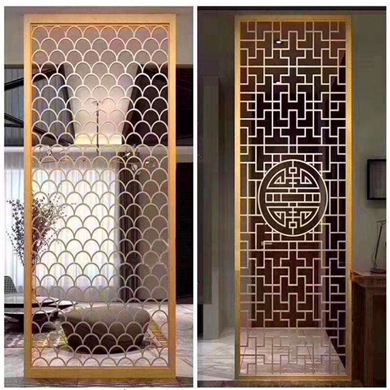

- Aluminum veneer customization, creating the art of personalized space

- The charm of aluminum veneer: not just surface craftsmanship

- Aluminum veneer customization, creating a new trend of personalized space!

- Curtain Wall Aluminum Veneer: The Beauty of Architecture, Starting from the First Board

- Curtain Wall Aluminum Veneer: The Perfect Integration of Architectural Aesthetics and Technology

Industry dynamics

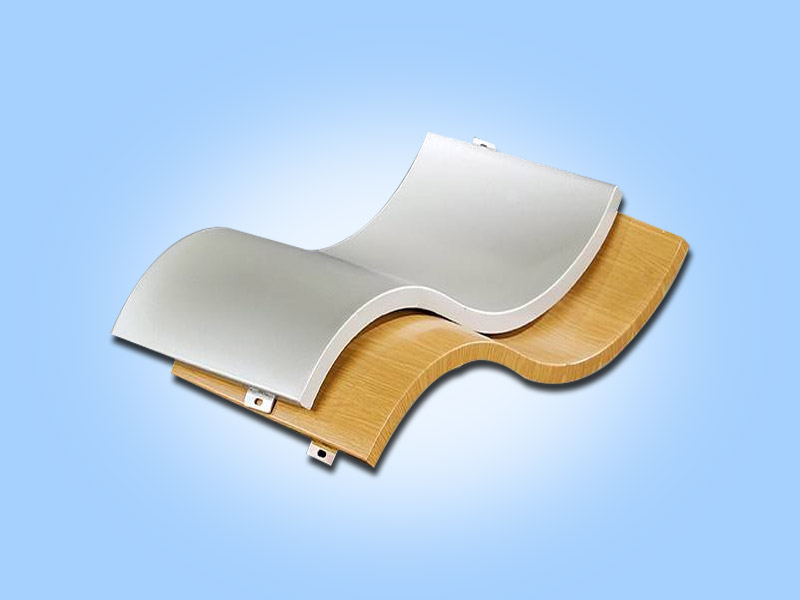

- Imitation wood grain aluminum veneer: a perfect fusion of modernity and nature

- Quality assurance of 2.5mm wood grain aluminum veneer

- Customize aluminum veneer to create an exclusive personalized space

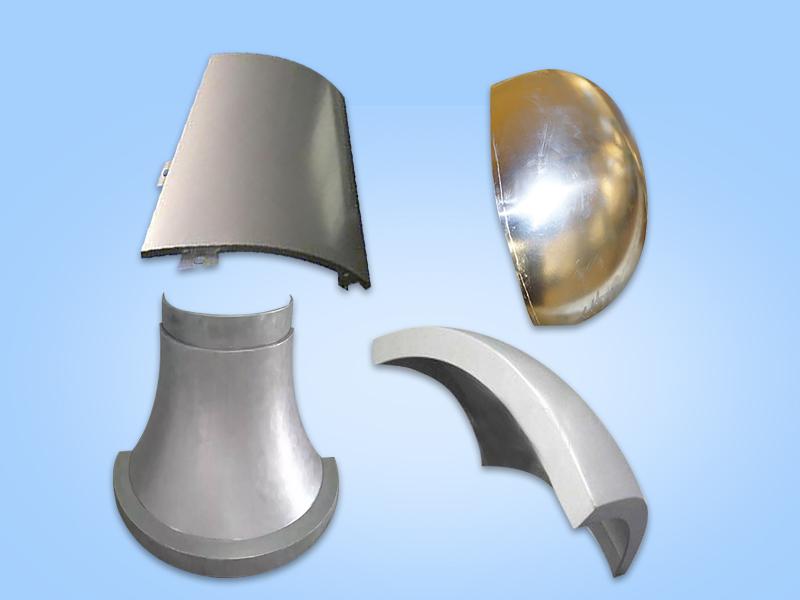

- Aluminum veneer curtain wall, the magnificent coat of architectural art

- Creating exclusive style customized aluminum veneer to make the building more high-end, atmospheric and upscale

Frequently asked questions

- Is the surface treatment method of aluminum veneer restricted?

- What are the types of aluminum veneer?

- How to evaluate the impact of the plasticity of aluminum veneer on the appearance of buildings?

- Does the production of aluminum veneer require certification?

- Will the thickness of aluminum veneer affect its service life?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

What are the effects of the thickness of the oxide film on aluminum veneer?

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: 2022-03-16 20:43:21

- Click:0

Aluminum veneerIt is a material widely used in fields such as construction and decoration, and its oxide film thickness is one of the important factors affecting its surface quality and durability. Below, we will provide a detailed introduction to the thickness of the oxide film on aluminum veneer and its impact.

1. Definition of oxide film thickness

The thickness of the oxide film refers to the thickness of the oxide film formed on the surface of aluminum veneer. Generally speaking, the thicker the oxide film, the better the surface quality of aluminum veneer, and it can also improve its durability and anti-corrosion performance.

1. Factors affecting the thickness of oxide film

The thickness of the oxide film on aluminum veneer is influenced by various factors, including:

(1) The quality and purity of raw materials;

(2) The quality and accuracy of processing technology and equipment;

(3) Production environment and conditions, etc.

1. Testing method for oxide film thickness

To test the thickness of the oxide film on aluminum veneer, the following methods are generally used:

(1) Optical microscopy method: By using an optical microscope to observe the thickness of the oxide film on the surface of aluminum veneer;

(2) Electrochemical method: By applying a certain voltage and current on the surface of aluminum veneer, the thickness of its oxide film is measured;

(3) X-ray diffraction method: By using an X-ray diffractometer to analyze the composition and structure of the oxide film on the surface of aluminum veneer, the thickness can be calculated.

1. Application scenarios of oxide film thickness

The thickness of the oxide film on aluminum veneer is mainly used in fields such as construction and decoration. For example, in high-end buildings, the thickness of the oxide film is required to be high due to the need to maintain the flatness and aesthetics of the aluminum veneer surface; In automobile manufacturing, aluminum veneer needs to have good corrosion resistance and wear resistance, so a high oxide film thickness is also required.

How to control the thickness of the oxide film on aluminum veneer?

In order to control the thickness of the oxide film on aluminum veneer, enterprises can take the following measures:

(1) Optimize the selection of raw materials and processing techniques to ensure their quality and purity;

(2) Strengthen the control of production environment and conditions to avoid adverse effects on the thickness of oxide film;

(3) Strictly follow quality standards for production and processing to ensure product quality and safety performance.

The thickness of the oxide film on aluminum veneer is one of the important factors affecting its surface quality and durability. Enterprises should choose suitable aluminum veneers according to actual needs and strictly follow quality standards for production and processing to ensure product quality and safety performance.

Customer service QQ

Customer service QQ