Industry information

Company News

- Imitation wood grain aluminum veneer: natural texture, a fashionable choice for modern architecture

- Aluminum veneer: making buildings more beautiful and practical

- Aluminum veneer curtain wall, the new darling of architectural aesthetics?

- The unique charm of wood grain aluminum veneer, a new choice for home decoration

- Wood grain aluminum veneer: a fashionable choice for modern home decor

Industry dynamics

- Design characteristics and application field analysis of twisted aluminum veneer

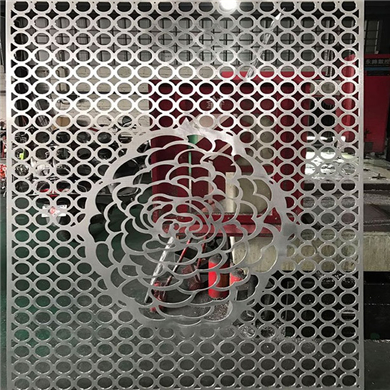

- Perforated carved aluminum veneer creates the artistic beauty of building facades

- Cleaning and maintenance techniques for aluminum ceiling

- Modern style aluminum veneer ceiling decoration

- Manufacturing process and technology of 3mm perforated aluminum veneer

Frequently asked questions

- Is the surface treatment method of aluminum veneer restricted?

- Can the insulation function of aluminum veneer improve the comfort of buildings?

- Will the thickness of aluminum veneer affect its service life?

- Can aluminum veneer be applied to the exterior design of high-rise buildings?

- Does the production of aluminum veneer require certification?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Aluminum veneer installation tools and methods

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: March 3, 2025 17:01:21

- Click:0

Aluminum veneerIt is a lightweight and high-strength building material widely used in fields such as construction and decoration. When installing aluminum veneer, it is necessary to use some professional tools and methods to ensure installation quality and effectiveness. This article will provide a detailed introduction to the installation tools and methods for aluminum veneer.

1. Installation tools

(1) Electric drill: used for drilling, punching and other operations.

(2) Electric hammer: used to strike harder materials such as concrete walls, stone, etc.

(3) Hand drill: used for drilling, punching and other operations, but with lower power.

(4) Cutting machine: used for cutting aluminum veneer and keel.

(5) Level gauge: used to measure the levelness of the ground and walls to ensure the installation level of aluminum veneer.

(6) Corner code and screwdriver: used to secure the connection between the keel and aluminum veneer.

(7) Hanging basket: used for transporting personnel and materials during high-altitude construction.

1. Installation method

(1) Preparation work: Before installation, it is necessary to inspect the aluminum veneer to confirm whether its size, color, quality, etc. meet the requirements. It is also necessary to prepare the necessary tools and materials, and clean up the construction site.

(2) Keel installation: First, install the keel on the wall or ceiling, and then fix the keel with the aluminum veneer connector. When fixing the connectors, attention should be paid to maintaining levelness to avoid tilting or twisting of the aluminum veneer.

(3) Aluminum veneer installation: Place the aluminum veneer on the keel in the position and direction required by the design, and adjust its levelness using a spirit level. Then use corner codes and screwdrivers to secure the aluminum veneer onto the keel. During the fixing process, attention should be paid to maintaining the flatness and verticality of the aluminum veneer to ensure its aesthetic effect.

(4) Detail processing: After installation, the joints of the aluminum veneer need to be treated to avoid water leakage or seepage. Sealing glue or other waterproof materials can be used for treatment. Attention should also be paid to the cleaning and maintenance of the surface of aluminum veneer to extend its service life.

The installation of aluminum veneer requires the use of professional tools and methods to ensure installation quality and effectiveness. Before installation, it is necessary to inspect and prepare the aluminum veneer, and pay attention to maintaining its levelness, verticality, and flatness. It is also necessary to treat the joints of the aluminum veneer to avoid water leakage or seepage.

Customer service QQ

Customer service QQ