Industry information

Company News

- Aluminum veneer customization, creating the art of personalized space

- Wood grain aluminum veneer: a fashionable choice for modern architecture

- Curtain wall aluminum veneer: an innovative tool for architectural aesthetics

- Aluminum veneer: the new darling of architectural aesthetics

- Aluminum veneer: the new darling of fashion in the industry?

Industry dynamics

- Characteristics and advantages of 3mm aluminum veneer ceiling

- Customize aluminum veneer to create your own home style

- Separated by a board, aluminum veneer curtain wall interprets modern architectural aesthetics

- 2. "New Fashion of Aluminum Materials - Exploration of the Charm of Imitation Wood Grain Aluminum Veneer" 3 Wood grain aluminum

- Wood grain aluminum veneer: the "new favorite of art" in the aluminum industry

Frequently asked questions

- What are the limitations of the application scope of aluminum veneer?

- How does aluminum veneer provide the wind resistance required for modern buildings?

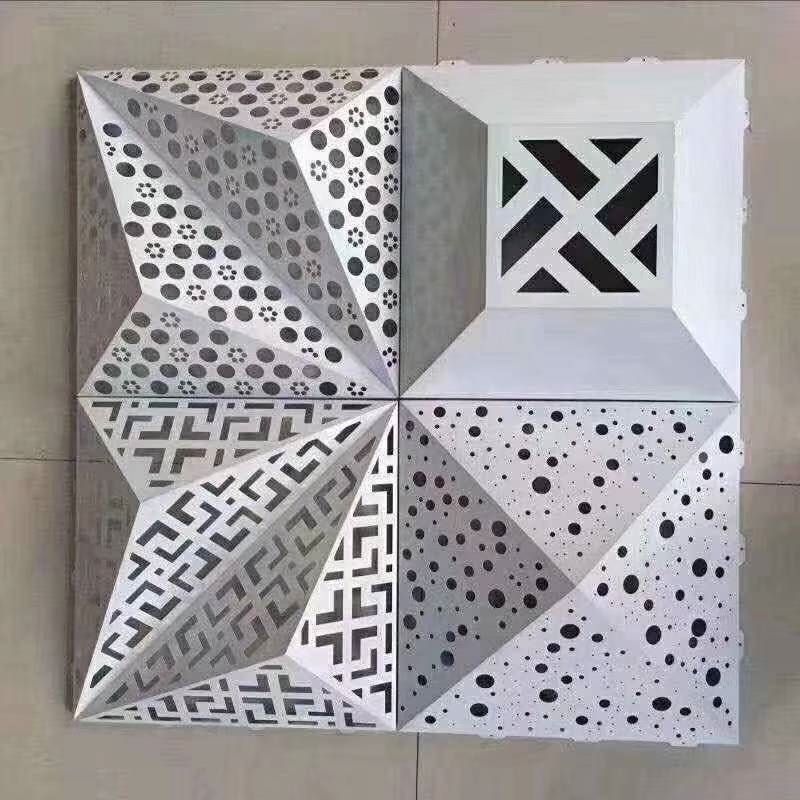

- How to evaluate the impact of the plasticity of aluminum veneer on the appearance of buildings?

- Does the production of aluminum veneer require certification?

- What are the types of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Detailed explanation of aluminum veneer installation process

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: 2022-03-05 05:43:08

- Click:0

Aluminum veneerAs a commonly used building material, its installation process is also one of its important construction stages. This article will provide a detailed introduction to the installation process of aluminum veneer from the aspects of material characteristics, installation tools, and methods.

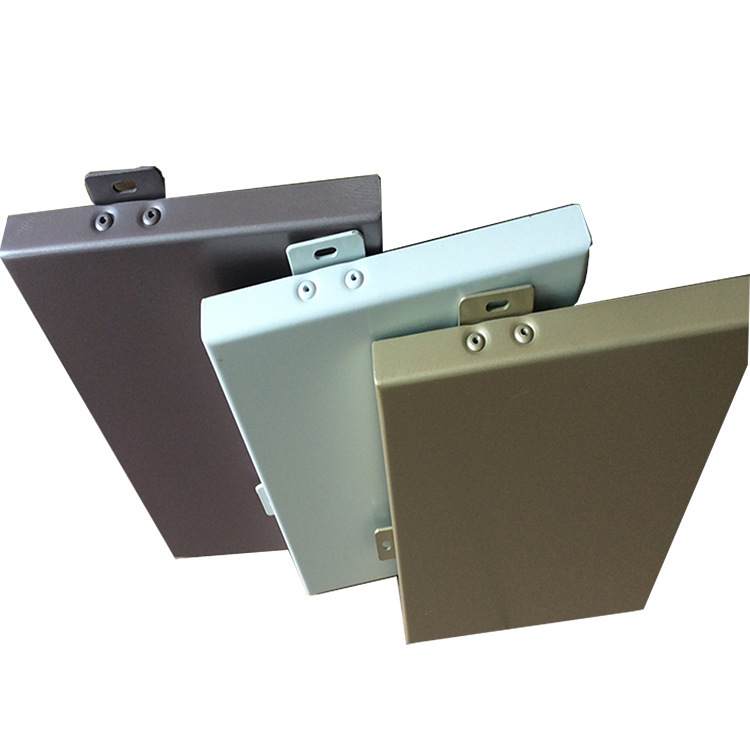

1、 Material characteristics of aluminum veneer

The main component of aluminum veneer is aluminum, which has advantages such as lightweight and corrosion resistance. Aluminum veneer also has good plasticity and processability, making it easy to design and manufacture various shapes and sizes. However, aluminum veneer also has certain fragility and insufficient rigidity, requiring attention to protection and fixation during installation.

2、 Installation tools and methods

The installation of aluminum veneer requires the use of specialized tools and methods, including drills, hammers, cutting machines, level gauges, steel wire ropes, etc. Electric drills and hammers are used for drilling and punching holes, cutting machines are used for cutting aluminum veneers, level gauges are used for measuring and adjusting levelness, and steel wire ropes are used for fixing and pulling.

The installation method of aluminum veneer mainly includes the following steps:

1. Determine installation location: Based on the structure and design requirements of the building, determine the installation location and direction of the aluminum veneer.

2. Drilling and punching: Use an electric drill or hammer to drill or punch holes on the aluminum veneer for subsequent installation and fixation.

3. Fixed keel: Fix the keel under the aluminum veneer, which can be a wooden keel or a metal keel, used to support the aluminum veneer and maintain its levelness.

4. Installation of aluminum veneer: Place the aluminum veneer on the keel and fix it to the keel with steel wire rope or other fixing methods.

5. Adjust the levelness: Use a level to adjust the levelness of the aluminum veneer to ensure that its flatness and verticality meet the requirements.

3、 Precautions

During the installation process of aluminum veneer, the following points should be noted:

1. Pay attention to protecting the surface of the aluminum veneer from scratches or damage.

2. When drilling and punching holes, be careful not to damage the structure and connection parts of the aluminum veneer.

3. When fixing the keel and aluminum veneer, appropriate tools and techniques should be used to ensure firm and reliable fixation.

4、 Conclusion

The installation process of aluminum veneer requires the use of specialized tools and methods, and attention should be paid to protecting the surface of the aluminum veneer, avoiding damage to the structure and connection parts, and other issues. Only by strictly following the installation process can the quality and service life of aluminum veneer be guaranteed.

- previous page:Aluminum veneer installation tools and methods

- Next page:Comparative analysis of aluminum veneer materials

Customer service QQ

Customer service QQ