Industry information

Company News

- Curtain wall aluminum veneer: the "invisible hero" of modern architecture

- Aluminum veneer: the 'invisible hero' in architecture

- Unveiling the 'Curtain Wall Aluminum Veneer': The Hidden Guardian of the Architecture Industry

- Aluminum veneer: the fashionable choice of modern architecture, revealing its charm!

- Aluminum veneer: the fashionable "coat" of architecture

Industry dynamics

- Installation skills of aluminum veneer for exterior wall ceiling

- Aluminum veneer curtain wall: the beauty of architecture, separated by a single panel

- The unique charm of imitation wood grain aluminum veneer, savoring the fashionable new trend of modern architecture

- How can aluminum veneer improve production efficiency?

- Aluminum veneer: the beauty of architecture, simplicity is not simple

Frequently asked questions

- What are the types of aluminum veneer?

- Can aluminum veneer be used for building platform design?

- Does the production of aluminum veneer require certification?

- How does aluminum veneer provide the wind resistance required for modern buildings?

- Can the insulation function of aluminum veneer improve the comfort of buildings?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Manufacturing process and technology of 3mm perforated aluminum veneer

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: 2022-03-15 07:25:49

- Click:0

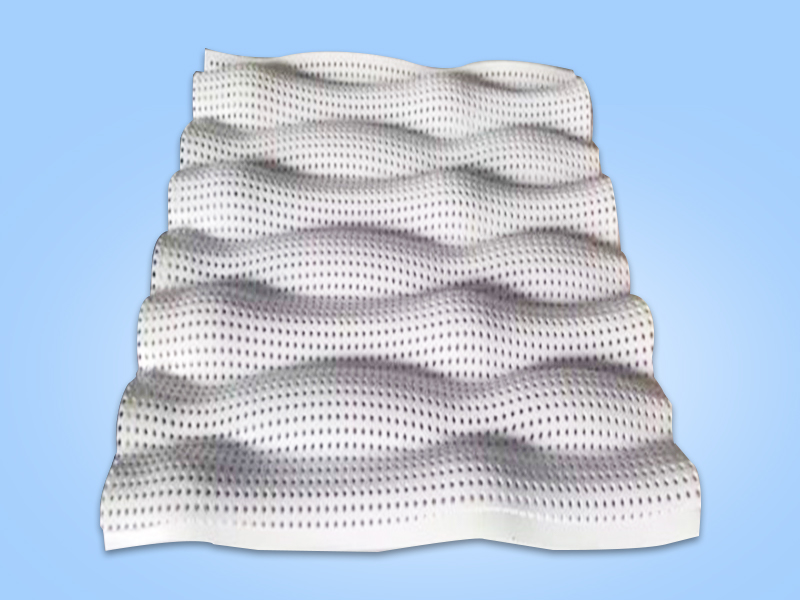

3mm perforationAluminum veneerIt is a new type of building material that has the advantages of lightweight, high strength, corrosion resistance, fire resistance, and sound insulation. And the realization of these advantages cannot be separated from the continuous innovation and improvement of its manufacturing process and technology. Below is a detailed introduction to the manufacturing process and technology of 3mm perforated aluminum veneer.

1、 Manufacturing process

1. Raw material selection: The raw materials for 3mm perforated aluminum veneer mainly include aluminum alloy and perforated core material. The selection of aluminum alloy needs to be based on specific usage environments and requirements to ensure its quality and performance. The selection of perforated core material needs to consider factors such as thickness, hardness, and strength to meet the usage requirements of 3mm perforated aluminum veneer.

2. Sheet metal processing: Cutting, bending, punching and other processing of aluminum alloy sheets to obtain the desired shape and size.

3. Perforation processing: Perforation processing is performed on aluminum alloy sheets to form the required holes. Perforation processing is an important step in the manufacturing process of 3mm perforated aluminum veneer, which requires high-precision equipment and technology to ensure the accuracy and quality of the holes.

4. Surface treatment: Surface treatment of perforated aluminum alloy sheets, including anodizing, spraying, electrophoretic coating, etc., to improve their corrosion resistance and aesthetics.

5. Assembly and installation: Assemble and connect the perforated aluminum alloy sheet with other components to form a complete 3mm perforated aluminum veneer product. Installation and debugging are also required to ensure its stability and safety during use.

2、 Manufacturing Technology

1. CNC machining technology: CNC machining technology is an efficient and precise machining method that can greatly improve the production efficiency and quality of 3mm perforated aluminum veneer. Through CNC machining technology, precise cutting, bending, punching and other processing of aluminum alloy sheets can be achieved.

2. Precision perforation technology: Precision perforation technology is a high-precision perforation processing technology that can achieve high-precision perforation of aluminum alloy sheets. By using precision perforation equipment and technology, the hole accuracy and quality of 3mm perforated aluminum veneer can be guaranteed.

3. Automated production line: Automated production line is a highly integrated production method that can greatly improve the production efficiency and quality of 3mm perforated aluminum veneer. By adopting an automated production line, it is possible to achieve automated processing and assembly connection of aluminum alloy sheets, thereby improving production efficiency and product quality.

4. Intelligent management system: The intelligent management system is a management method that integrates information technology, automation, and control, which can achieve comprehensive management and monitoring of the production process of 3mm perforated aluminum veneer. By adopting an intelligent management system, production efficiency and product quality can be improved, while also reducing production costs and management risks.

The continuous innovation and improvement of the manufacturing process and technology of 3mm perforated aluminum veneer are the key to achieving various excellent properties. Only through continuous technological innovation and service upgrades can we meet the needs and expectations of different customers and make greater contributions to the development of the construction industry.

Customer service QQ

Customer service QQ