Industry information

Company News

- Aluminum veneer curtain wall, the new darling of architectural aesthetics?

- Wood grain aluminum veneer: the beauty of the "Renaissance" in the aluminum industry

- Exploring Aluminum Veneers for Curtain Walls: The Secret Weapon of Modern Architectural Aesthetics

- Imitation wood grain aluminum veneer: a perfect fusion of modernity and nature

- Wood grain aluminum veneer: the fashionable choice for modern architecture?

Industry dynamics

- Aluminum veneer: not just sheet metal, but also a new chapter in the beauty of architecture

- Aluminum veneer customization, creating a new proposition for personalized space!

- Aluminum veneer: a low-key luxury choice in modern architecture

- Wood grain aluminum veneer: the "beauty responsibility" of the aluminum industry

- What is the surface treatment effect of aluminum veneer?

Frequently asked questions

- How to evaluate the impact of the plasticity of aluminum veneer on the appearance of buildings?

- Is the surface treatment method of aluminum veneer restricted?

- Will the thickness of aluminum veneer affect its service life?

- What are the limitations of the application scope of aluminum veneer?

- Can the insulation function of aluminum veneer improve the comfort of buildings?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Quality assurance of 2.5mm wood grain aluminum veneer

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: 2022-03-15 18:22:05

- Click:0

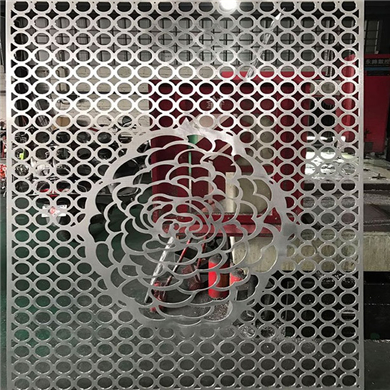

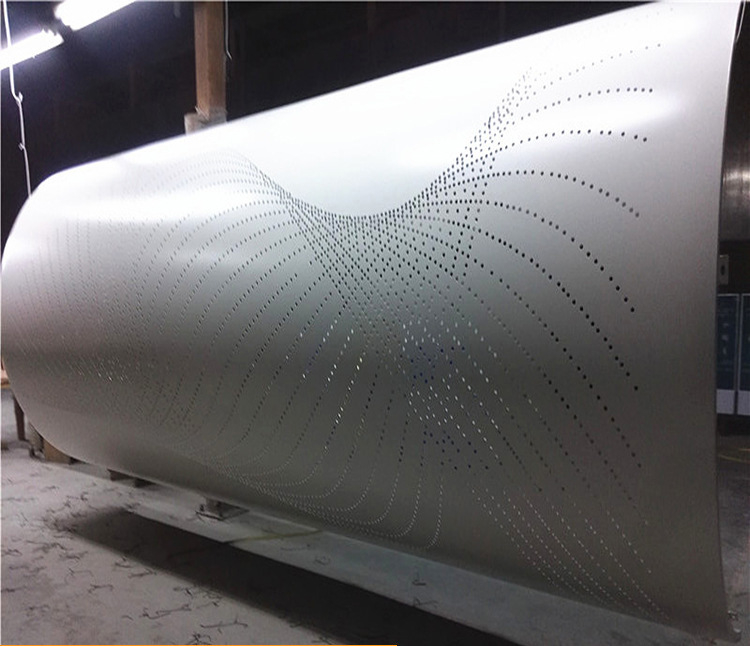

2.5mm wood grainAluminum veneerIt is a high-quality building material that presents a wood like texture on its surface, with advantages such as aesthetics, environmental friendliness, and durability. In the production process, manufacturers need to strictly control each link to ensure product quality and performance. Below, we will provide a detailed introduction to the quality assurance measures for 2.5mm wood grain aluminum veneer.

1、 Raw material procurement

1. High quality suppliers

Manufacturers need to choose high-quality raw material suppliers to ensure that the purchased raw materials meet national and industry standards. Regular audits and evaluations of suppliers are also necessary to ensure their quality and reputation.

1. Strict testing process

The manufacturer will conduct strict testing on the purchased raw materials, including chemical composition, physical properties, appearance, and other aspects. Only raw materials that meet the requirements will be used for production.

2、 Production process

1. Advanced production equipment

Manufacturers need to use advanced production equipment and technology to ensure the quality and performance of their products. For example, using automated production lines, high-precision CNC machine tools and other equipment can improve production efficiency while reducing the impact of human factors on product quality.

1. Strict process flow

Manufacturers need to establish strict process flow and quality management system to ensure that every production link meets the requirements. For example, inspection and testing are conducted for each process to ensure that the quality and performance of the product meet the standards.

3、 Quality inspection

1. Comprehensive product testing

The manufacturer will conduct comprehensive quality inspections on all products leaving the factory, including dimensional accuracy, surface flatness, strength, and other aspects. Only products that have passed testing will be sold to customers.

1. Professional testing institutions

Manufacturers will choose professional testing institutions to test their products to ensure that their performance and quality meet standards. These institutions usually have a high level of technical expertise and rich experience, and can provide accurate and reliable testing results.

4、 After sales service

1. Timely after-sales service

Manufacturers need to provide timely after-sales service, including product installation guidance, maintenance, and other aspects. Only by promptly resolving customer issues can we improve customer satisfaction and loyalty.

1. A comprehensive complaint handling mechanism

Manufacturers need to establish a sound complaint handling mechanism to promptly address customer issues and feedback. This can not only improve customer satisfaction, but also help companies continuously improve product quality and service levels.

The quality assurance measures for 2.5mm wood grain aluminum veneer include raw material procurement, production process, quality inspection, and after-sales service. Only through strict control and management can we ensure that the quality and performance of our products meet standards and provide customers with high-quality products and services.

Customer service QQ

Customer service QQ