Industry information

Company News

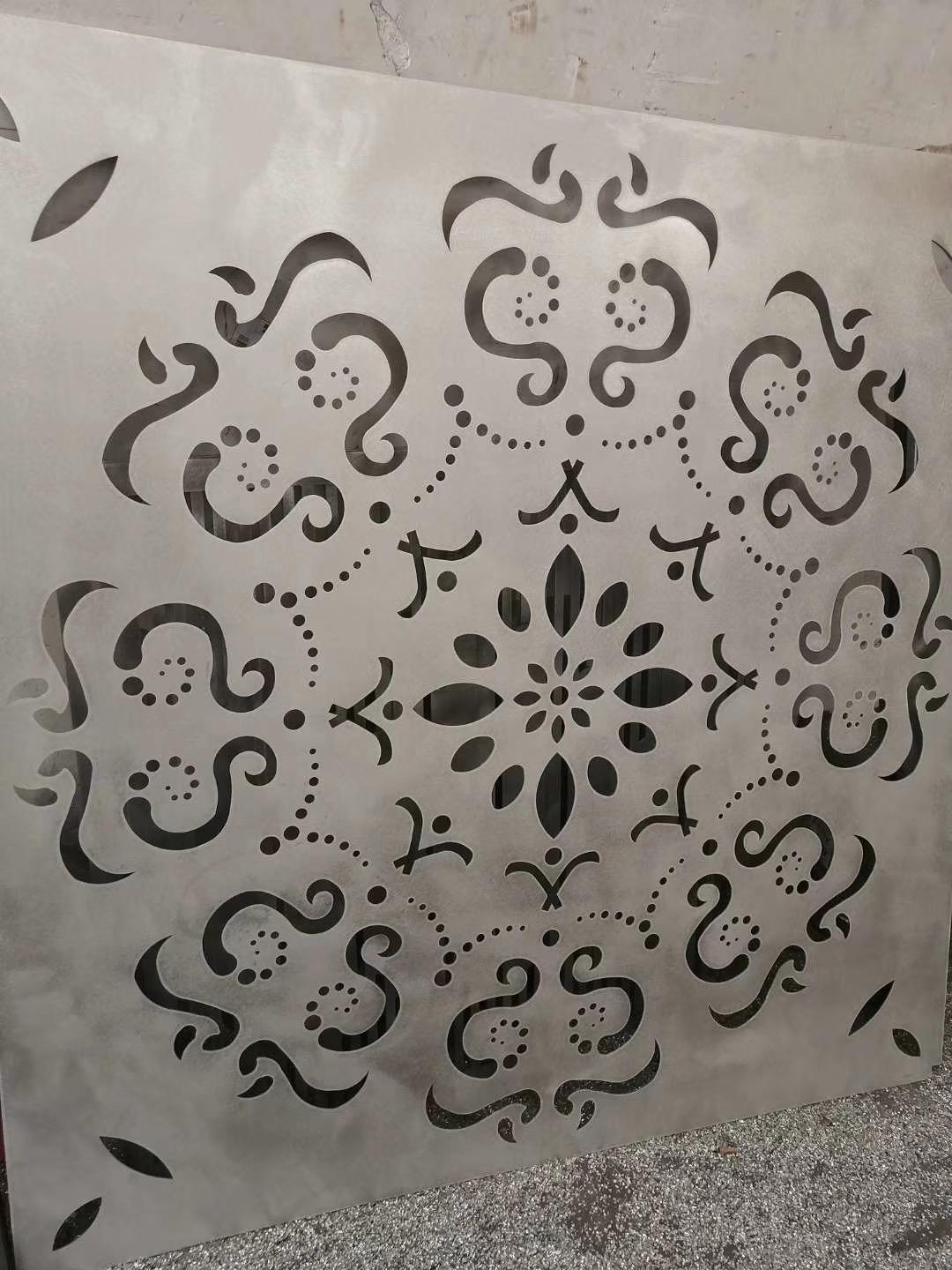

- Aluminum veneer: not just building materials, but also the art of architecture

- Aluminum veneer: the new darling of architectural aesthetics

- Dear readers, have you ever thought that there can be a balance between modern architecture and retro elements

- Imitation Wood Grain Aluminum Veneer: The Natural Beauty in Modern Architecture

- Wood grain aluminum veneer, a new choice for retro style in modern architecture

Industry dynamics

- Design Specification for Imitation Wood Grain Aluminum Veneer

- Imitation wood grain aluminum veneer: the new favorite of modern architecture, the perfect integration of nature and technology

- What is the impact resistance of aluminum veneer?

- How to prevent aluminum veneer from being contaminated during use?

- Aluminum veneer: the fashionable choice of modern architecture, revealing its charm

Frequently asked questions

- Can the insulation function of aluminum veneer improve the comfort of buildings?

- Can aluminum veneer be used for building platform design?

- How to evaluate the impact of the plasticity of aluminum veneer on the appearance of buildings?

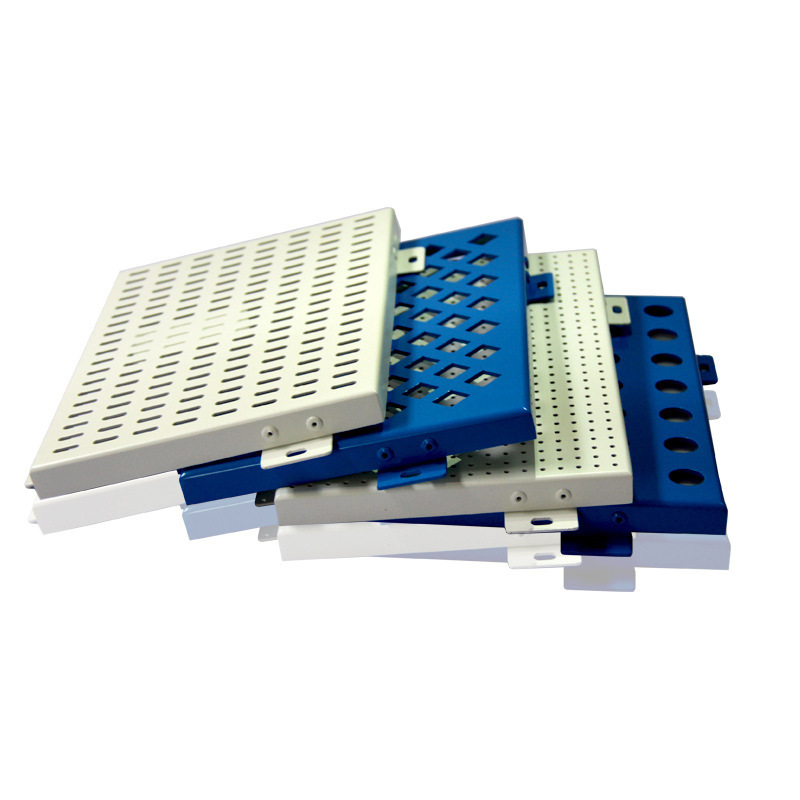

- What are the types of aluminum veneer?

- What are the limitations of the application scope of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Anodizing treatment of aluminum veneer

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: 2022-03-04 19:38:47

- Click:0

FluorocarbonAluminum veneerIt is a very practical building material with advantages such as lightweight, high strength, and corrosion resistance, which can meet people's diverse needs for building decoration materials. With the increasing demand for the performance of building decoration materials, fluorocarbon aluminum veneer has gradually become a material that has undergone anodizing treatment. Below is a detailed introduction to the performance of fluorocarbon aluminum veneer in anodizing treatment.

1、 Process flow

The anodizing process of fluorocarbon aluminum veneer mainly includes the following steps: cleaning, coating, electrolysis, water washing, and drying. Specifically, the surface of the aluminum veneer needs to be cleaned first to remove impurities and oil stains from the surface; Then apply a layer of special coating agent on the surface of the aluminum veneer to form a protective film; Next, electrolytic treatment is carried out to cause a chemical reaction in the coating layer, forming a layer of oxide film; Finally, water washing and drying are carried out to remove excess moisture and chemicals, completing the anodizing process.

2、 Processing effect

After anodizing treatment, a hard, wear-resistant, and corrosion-resistant oxide film will form on the surface of fluorocarbon aluminum veneer, thereby improving its surface hardness and wear resistance. Due to the fact that the color of the oxide film is mostly white or gray, it can also enhance the decorative effect of fluorocarbon aluminum veneer. After anodizing treatment, the surface of fluorocarbon aluminum veneer also has good anti fouling and self-cleaning properties, and is not easily contaminated with dust and dirt, maintaining its beauty and service life.

3、 Application scope

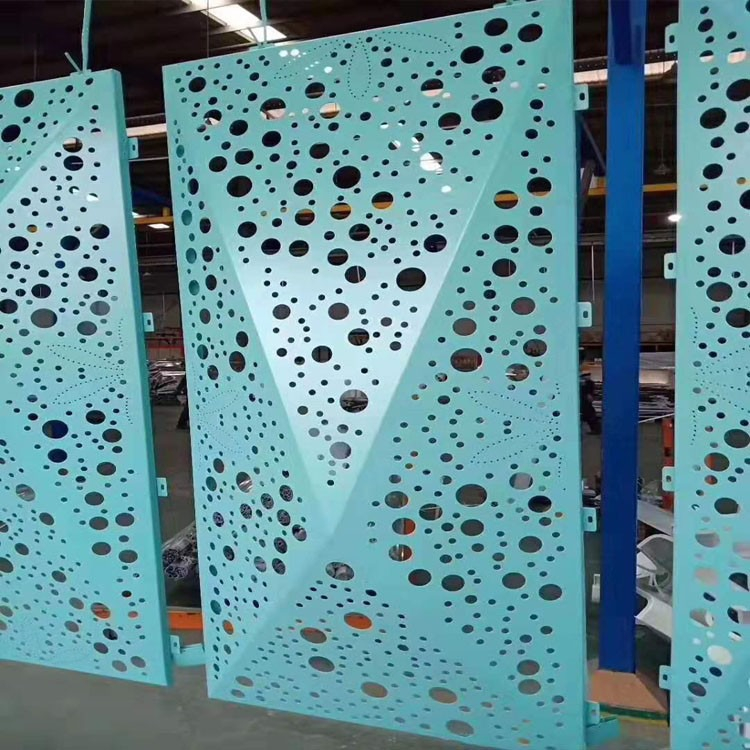

Due to the fact that anodizing treatment can improve the surface properties and decorative effect of fluorocarbon aluminum veneer, it is widely used in various occasions of architectural decoration. For example, in commercial spaces, fluorocarbon aluminum veneer treated with anodizing can be used to create a fashionable and high-end effect; In residential areas, one can choose fluorocarbon aluminum veneer that has undergone anodizing treatment to create a warm and comfortable atmosphere. It is also possible to combine anodized fluorocarbon aluminum veneer with other decorative materials such as wood and stone to create a more diverse and colorful architectural decoration effect.

4、 Easy maintenance and upkeep

Since the fluorocarbon aluminum veneer after anodic oxidation treatment has good durability and anti-aging performance, it does not need frequent maintenance during use. Just regularly clean the surface of dust and dirt to maintain its appearance and service life. Fluorocarbon aluminum veneer also has good fire resistance and sound insulation performance, providing better protection for people's lives.

Fluorocarbon aluminum veneer treated with anodizing has many advantages and characteristics. When choosing building materials, we should pay attention to the characteristics of the product's material, process, design, and treatment effect to ensure the safety, aesthetics, and durability of the building.

Customer service QQ

Customer service QQ