Industry information

Company News

- The charm of wood grain aluminum veneer: the perfect fusion of nature and craftsmanship

- Aluminum veneer customization, creating a new choice for personalized space!

- Aluminum veneer curtain wall: a perfect fusion of architectural aesthetics and practicality

- Aluminum veneer: the "fashionable coat" of modern architecture

- Aluminum veneer, the little secret to making buildings look brand new!

Industry dynamics

- Wood grain aluminum veneer, a fashionable choice for modern home decor

- Innovative painted 2.5mm aluminum veneer showcases individual style

- Exploration of the application of curtain wall aluminum square tube in architecture

- What is the role of aluminum veneer in construction?

- Imitation wood grain aluminum veneer, a new favorite of modern and traditional wall design

Frequently asked questions

- Can the insulation function of aluminum veneer improve the comfort of buildings?

- How to evaluate the impact of the plasticity of aluminum veneer on the appearance of buildings?

- What are the types of aluminum veneer?

- Is the surface treatment method of aluminum veneer restricted?

- What are the limitations of the application scope of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

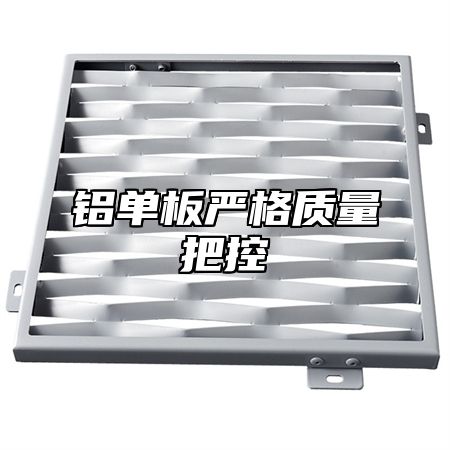

Strict quality control of aluminum veneer

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: March 4, 2025 01:44:47

- Click:0

Aluminum veneerAs a new type of building material, it has the characteristics of lightweight, corrosion resistance, and fire resistance, and is widely used in the field of building decoration. In the decoration process of aluminum veneer, strict quality control is also a very important link. Only through strict quality control can the decorative effect and service life of aluminum veneer be guaranteed. Below is a detailed introduction to the strict quality control of aluminum veneer.

1、 Raw material quality

The quality of aluminum veneer first depends on the quality of its raw materials. High quality aluminum alloy materials can ensure that aluminum veneers have good strength and toughness, while also improving their corrosion resistance and service life. When producing aluminum veneer, strict quality inspection of raw materials is required to ensure that they meet national standards.

2、 Production process

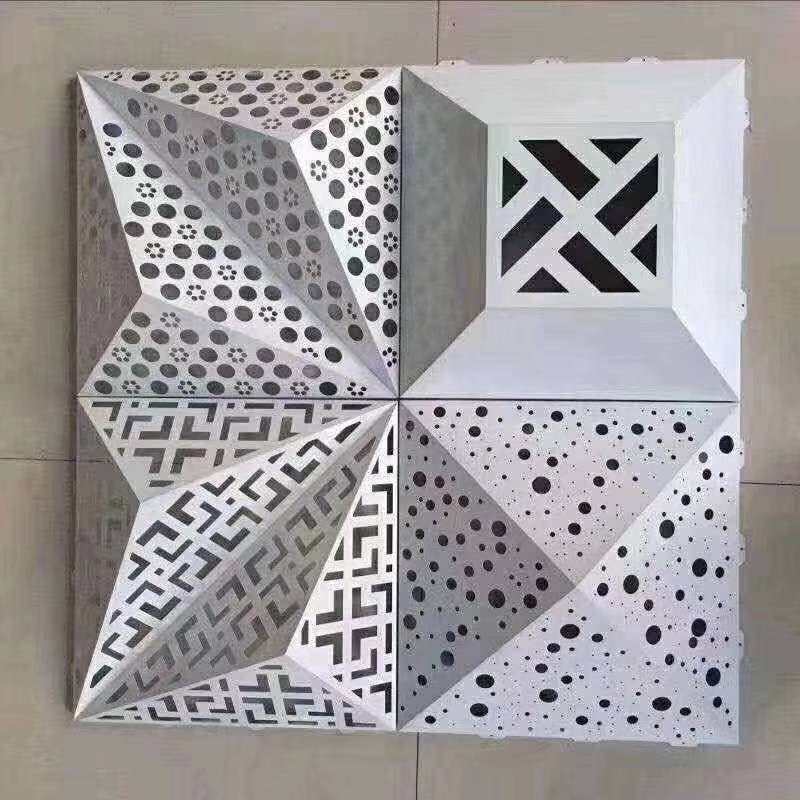

The production process of aluminum veneer is also one of the important factors affecting its quality. High quality production technology can ensure the dimensional accuracy and surface flatness of aluminum veneer, thereby improving its decorative effect. The production process can also determine indicators such as the strength and corrosion resistance of aluminum veneer. When producing aluminum veneer, advanced production processes are required and production must strictly follow national standards.

3、 Surface treatment

The surface treatment method of aluminum veneer can also affect its quality. High quality surface treatment methods can improve the corrosion resistance, aesthetics, and service life of aluminum veneer. The commonly used surface treatment methods currently include anodizing, electrophoretic coating, powder coating, etc. When producing aluminum veneer, it is necessary to choose a suitable surface treatment method according to actual usage needs and strictly follow national standards for treatment.

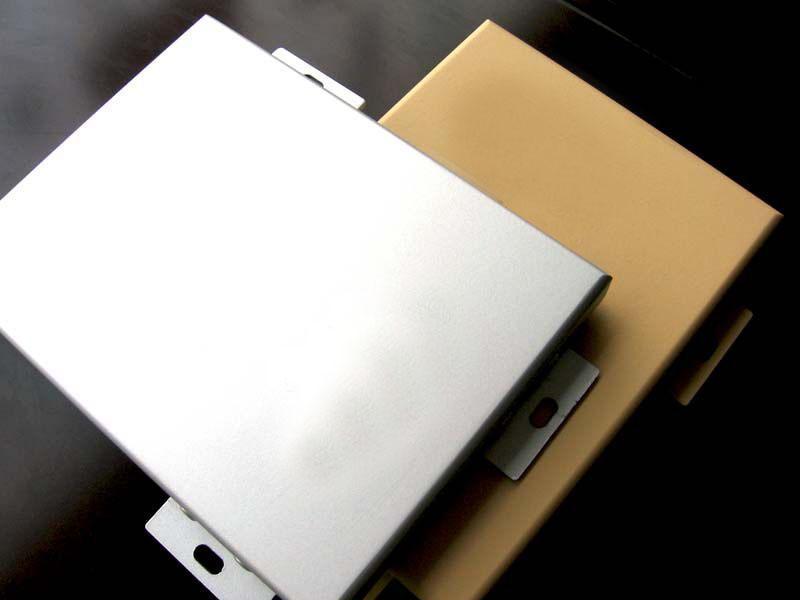

4、 Thickness and strength

The thickness and strength of aluminum veneer are also important factors affecting its quality. Generally speaking, the thicker the thickness, the higher the strength, but the price will also increase accordingly. When producing aluminum veneer, it is necessary to choose according to actual needs and ensure that its thickness and strength meet national standard requirements.

5、 Testing and Certification

High quality aluminum veneer needs to pass relevant testing and certification before it can be put on the market for sale. At present, the main domestic testing and certification institutions include China Quality Certification Center (CQC) and China Construction Metal Structure Association. When producing aluminum veneer, it is necessary to conduct strict testing and certification, and ensure that it has passed relevant testing and certification, and has corresponding testing reports.

The above five aspects are one of the main strict quality control measures in the current aluminum veneer industry. In the future, with the continuous improvement of people's requirements for building decoration quality, the aluminum veneer industry will continue to develop towards a more efficient and reliable direction.

Customer service QQ

Customer service QQ