Industry information

Company News

- Aluminum veneer curtain wall: a model of the integration of architectural aesthetics and technology

- Curtain wall aluminum veneer: a perfect combination of architectural aesthetics and practicality

- Aluminum veneer, creating a new trend in future architecture

- Aluminum veneer curtain wall, the fashionable outerwear of modern architecture

- Wood grain aluminum veneer: a fashionable element in modern architecture

Industry dynamics

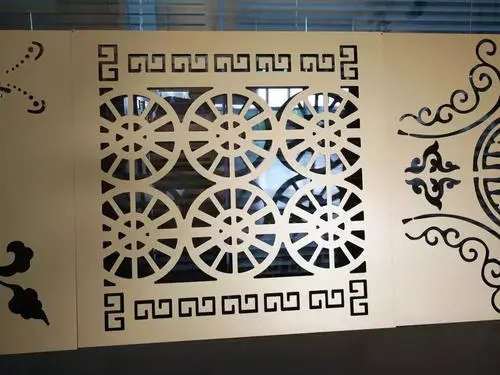

- Aluminum veneer customization, creating your own personalized space

- Application of Aluminum Veneer in Airport Buildings

- Color selection guide for 3mm aluminum veneer

- What is the production process of curtain wall aluminum veneer?

- Cleaning and maintenance techniques for aluminum ceiling

Frequently asked questions

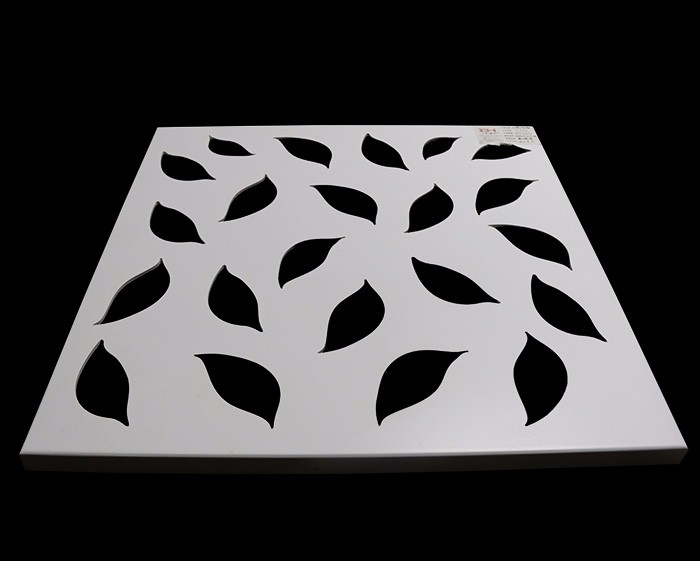

- What are the types of aluminum veneer?

- Can the insulation function of aluminum veneer improve the comfort of buildings?

- How does aluminum veneer provide the wind resistance required for modern buildings?

- Can aluminum veneer be applied to the exterior design of high-rise buildings?

- Will the thickness of aluminum veneer affect its service life?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

What is the anti deformation performance of aluminum veneer?

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: 2022-03-11 05:01:11

- Click:0

Aluminum veneerIt is a material widely used in fields such as architecture and decoration, and its deformation resistance has a significant impact on its service life and aesthetic appearance. This article will provide a detailed introduction to the anti deformation performance of aluminum veneer and its influencing factors.

1、 Anti deformation performance of aluminum veneer

The anti deformation performance of aluminum veneer refers to its ability to not undergo significant deformation or damage under external forces. Generally speaking, the better the deformation resistance of aluminum veneer, the longer its service life and aesthetic appearance.

2、 Factors affecting the deformation resistance of aluminum veneer

The anti deformation performance of aluminum veneer is influenced by various factors, mainly including the following aspects:

1. Characteristics of the material itself

The material of aluminum veneer itself has certain rigidity and elasticity, which is the basis for its ability to resist external forces. However, the rigidity and elasticity of different materials also vary, which can affect the deformation resistance of aluminum veneer.

1. Surface treatment process

After different treatment processes on the surface of aluminum veneer, its hardness and wear resistance will also be improved, thereby enhancing its ability to resist deformation. For example, surface treatment processes such as anodizing and electrophoretic coating can improve the hardness and wear resistance of aluminum veneer.

1. Use environment and conditions

The usage environment and conditions of aluminum veneer can also affect its ability to resist deformation. For example, in harsh environments such as high temperature, high humidity, and strong winds, aluminum veneers are prone to deformation and damage.

1. Installation method and approach

The installation method and technique of aluminum veneer can also affect its ability to resist deformation. If installed improperly or using inappropriate support structures, it can cause excessive pressure or tension on the aluminum veneer, leading to deformation or damage.

3、 How to improve the deformation resistance of aluminum veneer?

To improve the deformation resistance of aluminum veneer, the following aspects can be taken into consideration:

1. Choose high-quality raw materials

Choosing high-quality raw materials can ensure that aluminum veneer has high strength and stiffness, thereby improving its resistance to deformation. The performance of aluminum veneer can also be optimized by adjusting the proportion and mix ratio of raw materials.

1. Adopt appropriate surface treatment processes

Customer service QQ

Customer service QQ