Industry information

Company News

- The modern charm of imitation wood grain aluminum veneer: the perfect encounter of nature and technology

- Aluminum veneer customization, creating a new proposition for personalized space

- The fashionable charm of wood grain aluminum veneer: a green choice for modern architecture

- Wood grain aluminum veneer: natural texture, a fashionable choice for modern architecture

- Aluminum veneer customization, creating the art of personalized space

Industry dynamics

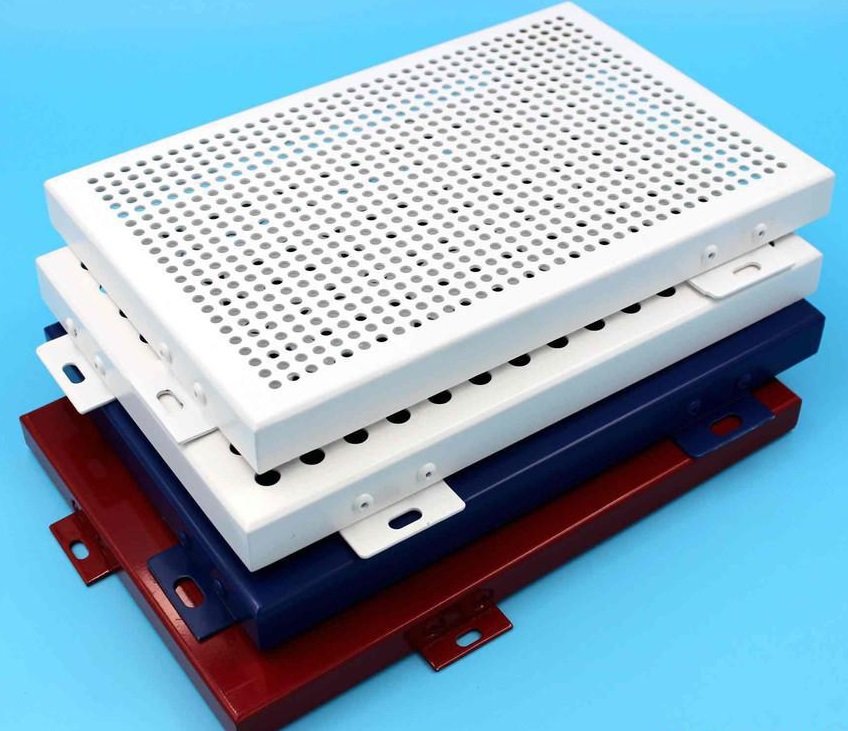

- Punched aluminum veneer is a key element in creating extraordinary architecture

- Refrigeration molded aluminum veneer system

- Analysis of Price Trends in the Aluminum Veneer Market

- Wood grain aluminum veneer: metal interpretation of natural texture

- 2. New trend of aluminum plate, imitating wood grain to interpret spatial aesthetics. 3 Imitation wood grain aluminum veneer: modern

Frequently asked questions

- Is the surface treatment method of aluminum veneer restricted?

- Can aluminum veneer be used for building platform design?

- What are the limitations of the application scope of aluminum veneer?

- How does aluminum veneer provide the wind resistance required for modern buildings?

- Will the thickness of aluminum veneer affect its service life?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

What is the production process of curtain wall aluminum veneer?

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: 2022-03-05 07:09:50

- Click:0

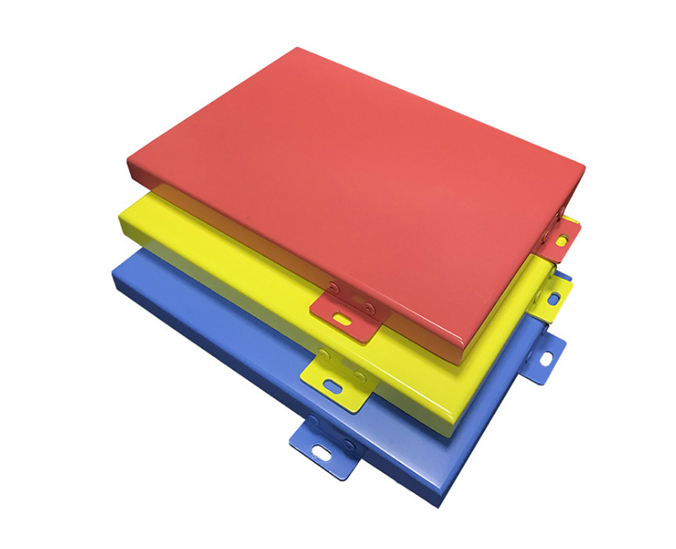

curtainAluminum veneerAs a common exterior wall decoration material, its production process is also very important. The production process of curtain wall aluminum veneer not only affects its quality and performance, but also directly affects the overall quality and value of the building. Below is a detailed introduction to the production process of curtain wall aluminum veneer.

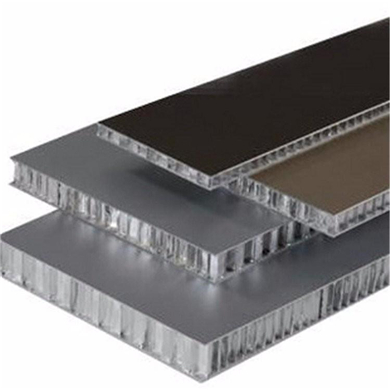

The raw material preparation stage is an important link in the production of curtain wall aluminum veneer. At this stage, it is necessary to screen and inspect the raw materials used to ensure that they comply with relevant national standards and specifications. Generally speaking, the main raw materials for curtain wall aluminum veneer include aluminum alloy sheets, polyurethane insulation materials, fiberglass mesh cloth, etc.

The pre-processing stage is a crucial step in the production of aluminum veneer for curtain walls. At this stage, it is necessary to perform surface treatment on the raw materials to improve their surface hardness and wear resistance. Generally, anodizing or electrophoretic coating processes are used to form a dense and uniform oxide film or coating.

The forming stage is the core process of producing aluminum veneer for curtain walls. At this stage, it is necessary to process and shape the pre treated raw materials to form the desired shape and size of the curtain wall aluminum veneer. Generally, stamping, stretching, rolling and other processing methods are used to achieve high-precision and high-quality forming effects.

Next, the surface treatment stage is a necessary step in the production of curtain wall aluminum veneer. At this stage, it is necessary to perform surface treatment on the formed curtain wall aluminum veneer to further improve its surface hardness and wear resistance. Generally, treatment methods such as spraying polyurethane insulation materials are used to form a coating with good insulation performance and durability.

The installation and maintenance phase is an important link in the production of curtain wall aluminum veneer. At this stage, it is necessary to regularly clean and maintain the installed curtain wall aluminum panels to maintain their appearance and service life. It is necessary to carry out necessary maintenance and replacement of the curtain wall aluminum veneer according to the actual situation, in order to extend its service life and maintain its good performance.

The production process of curtain wall aluminum veneer is influenced by various factors. When selecting and using curtain wall aluminum panels, a comprehensive evaluation should be conducted based on factors such as the building's usage needs, budget, and maintenance costs to achieve better cost-effectiveness and usage effects. It is also necessary to pay attention to the quality certification, production process, and testing reports of curtain wall aluminum panels to ensure that they comply with relevant national standards and specifications.

Customer service QQ

Customer service QQ