Industry information

Company News

- Personalized aluminum veneer customization, making buildings more fashionable and trendy

- Imitation wood grain aluminum veneer, creating a natural aesthetic space!

- Aluminum veneer curtain wall: architectural artwork interwoven with light and shadow

- Aluminum veneer customization, creating a new choice for personalized space!

- Imitation wood grain aluminum veneer: natural texture, a fashionable choice for modern architecture

Industry dynamics

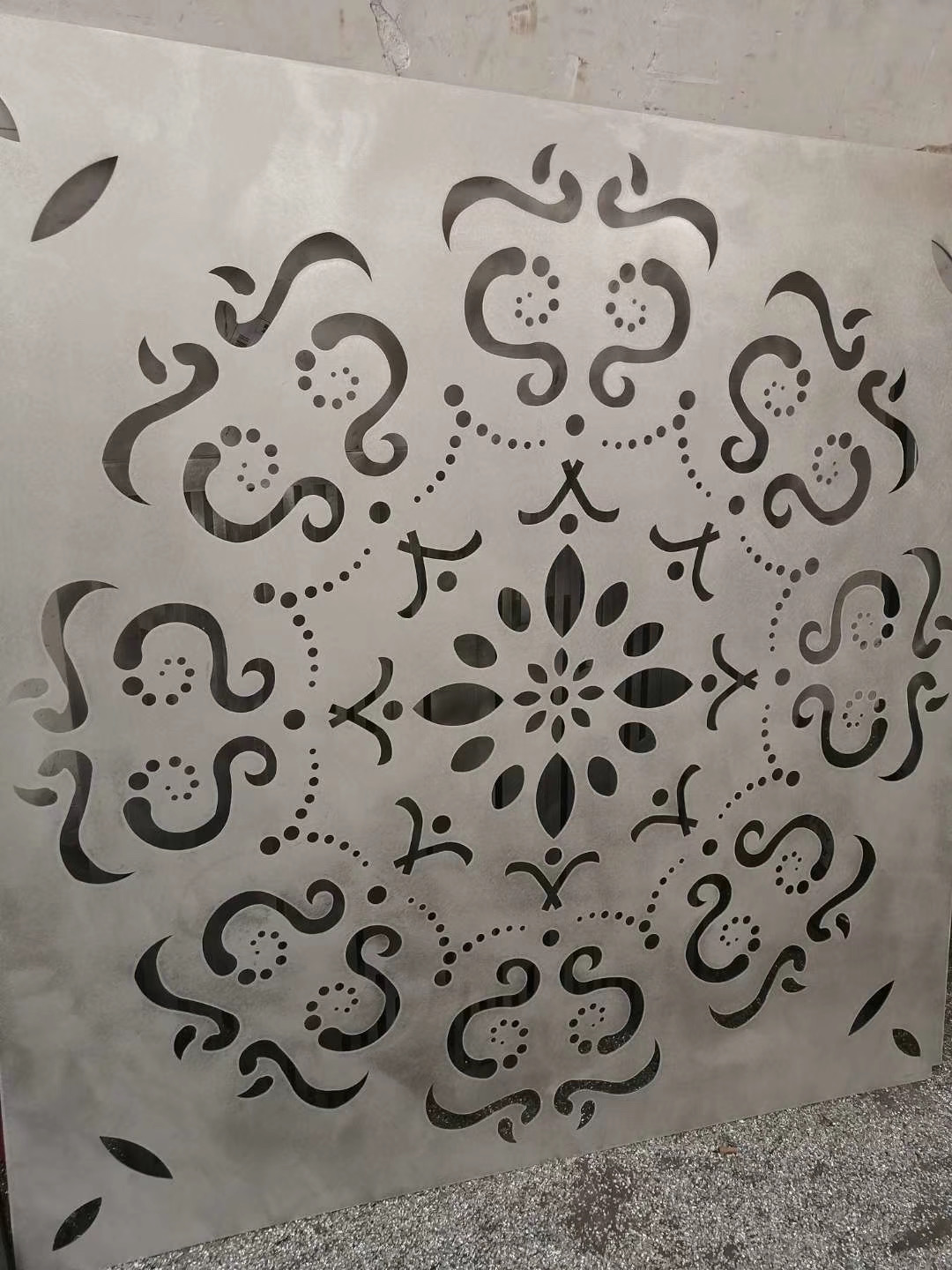

- Punched aluminum veneer is a key element in creating extraordinary architecture

- Customized aluminum veneer adds unique charm to buildings

- Wood grain honeycomb aluminum plate creates a natural and comfortable home environment

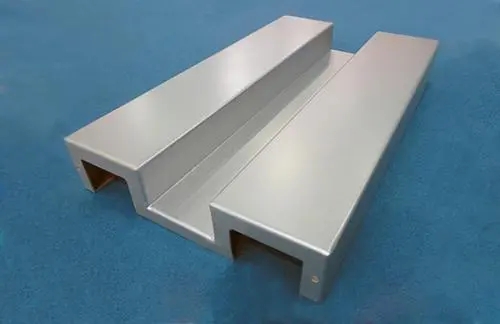

- What is the production process of curtain wall aluminum veneer?

- The perfect combination of high-efficiency anti-corrosion and beauty of fluorocarbon aluminum veneer

Frequently asked questions

- How to evaluate the impact of the plasticity of aluminum veneer on the appearance of buildings?

- How does aluminum veneer provide the wind resistance required for modern buildings?

- Does the production of aluminum veneer require certification?

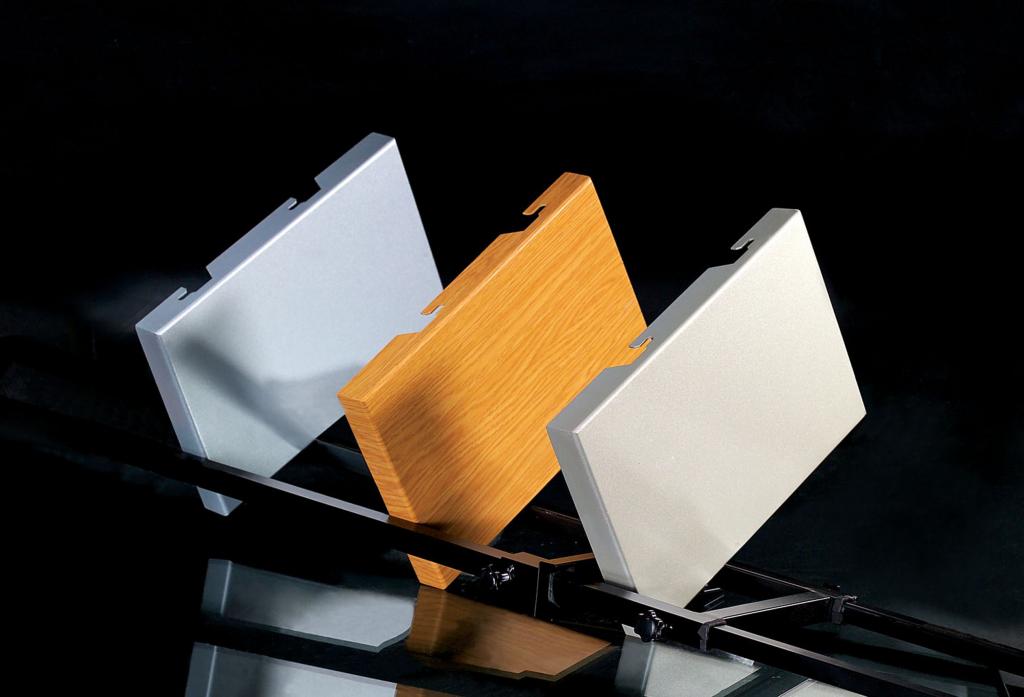

- What are the types of aluminum veneer?

- Will the thickness of aluminum veneer affect its service life?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Aluminum veneer manufacturer selection guide

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: 2022-03-09 02:39:31

- Click:0

Aluminum veneerAs a building decoration material, its selection is an important link for customers to choose. Below is a detailed introduction to the selection strategy for aluminum veneer manufacturers.

1、 Understand product performance

1. Material properties: The main material of aluminum veneer is aluminum, and it is important to understand the physical and chemical properties of aluminum in order to select suitable products.

2. Surface treatment: There are various methods for surface treatment of aluminum veneer, such as spraying, anodizing, powder coating, etc. It is important to understand the characteristics and applicable scope of each treatment method.

3. Strength and stability: The strength and stability of aluminum veneer are important performance indicators, and products that meet national standards should be selected.

2、 Consider the usage environment

1. Climate conditions: The use environment of aluminum veneer should take into account climate conditions such as temperature, humidity, etc., in order to select suitable products.

2. Place of use: The use of aluminum veneer should also be considered, such as indoor, outdoor, coastal areas, etc., in order to choose suitable products.

3. Installation method: There are also various installation methods for aluminum veneer, such as dry hanging, wet pasting, etc., and the appropriate installation method should be selected according to the actual situation.

3、 Pay attention to product quality

1. Thickness and weight: The thickness and weight of aluminum veneer are important quality indicators, and products that meet national standards should be selected.

2. Coating thickness: The coating thickness of aluminum veneer is also an important quality indicator, and products with uniform coating and thickness that meets standard requirements should be selected.

3. Flatness and angle: The flatness and angle of aluminum veneer are also important quality indicators, and products with high flatness and accurate angle should be selected.

4、 Compare prices and services

1. Price comparison: The price of aluminum veneer varies depending on factors such as brand, model, and specifications. A thorough price comparison should be conducted and products with high cost-effectiveness should be selected.

2. Service comparison: The after-sales service provided by aluminum veneer manufacturers is also an important consideration, and brands and manufacturers that provide comprehensive after-sales service should be chosen.

The selection guide for aluminum veneer manufacturers mainly includes understanding product performance, considering usage environment, paying attention to product quality, and comparing prices and services. In the actual operation process, it is necessary to follow relevant norms and standards for operation and management, strengthen communication and collaboration, and improve work efficiency and quality level. We also need to pay attention to issues such as environmental protection and energy conservation, continuously innovate and improve products and services, and meet the needs of customers and the expectations of society.

Customer service QQ

Customer service QQ