Industry information

Company News

- Wood grain aluminum veneer: the new favorite of modern architectural aesthetics

- The charm of aluminum veneer: not just surface craftsmanship

- New trend of aluminum plate: Imitation wood grain aluminum veneer, the beauty of collision between modern and traditional

- Aluminum veneer curtain wall: the fashionable coat of modern architecture

- Aluminum veneer: the fashionable outerwear of modern architecture

Industry dynamics

- Imitation wood grain aluminum veneer, creating a new trend of natural style

- How to optimize the installation time of aluminum veneer?

- Is the maintenance cost of aluminum veneer high?

- Wood grain aluminum veneer: a perfect fusion of nature and industry

- Aluminum veneer: the "green skin" of modern architecture

Frequently asked questions

- Will the thickness of aluminum veneer affect its service life?

- Does the production of aluminum veneer require certification?

- Can the insulation function of aluminum veneer improve the comfort of buildings?

- Can aluminum veneer be applied to the exterior design of high-rise buildings?

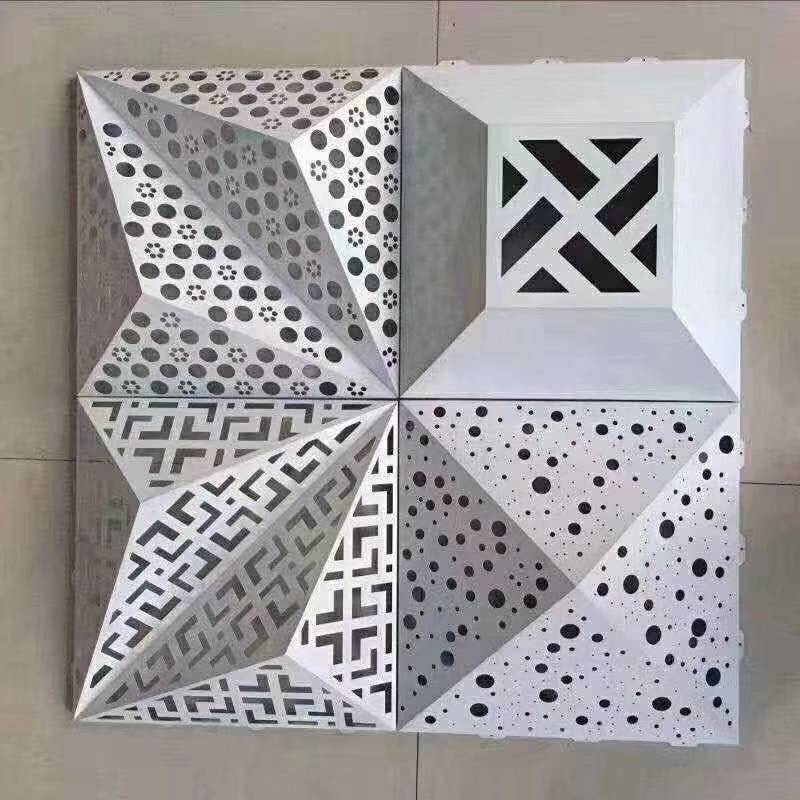

- How to evaluate the impact of the plasticity of aluminum veneer on the appearance of buildings?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

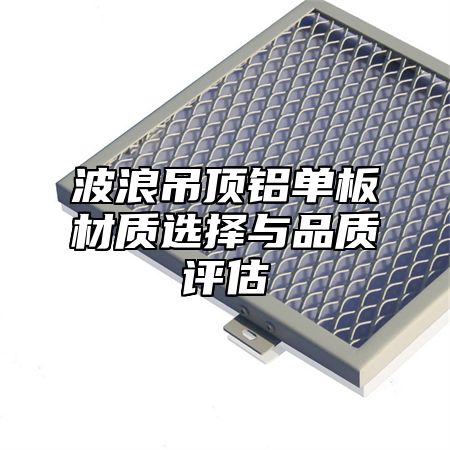

Material selection and quality evaluation of corrugated ceiling aluminum veneer

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: 2022-03-17 12:07:03

- Click:0

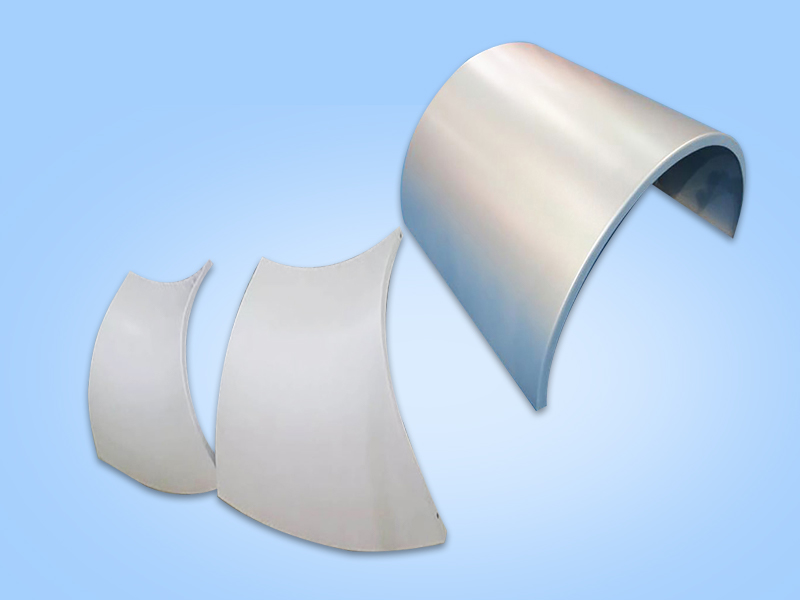

Wave ceilingAluminum veneerIt is a commonly used building decoration material, and the selection and quality evaluation of its materials are of great significance for ensuring the beauty and comfort of indoor environments. This article will provide a detailed introduction to the material selection and quality evaluation methods for corrugated ceiling aluminum veneer.

1、 Material selection

1. Aluminum alloy: The main material of the corrugated ceiling aluminum veneer is aluminum alloy, which has good strength and corrosion resistance. Aluminum alloy also has good processing performance and plasticity, and can be customized according to different design requirements.

2. Polyester fiber: The surface of the corrugated ceiling aluminum veneer is usually covered with polyester fiber material, which has good wear resistance and pollution resistance, and can extend the service life of the aluminum veneer.

3. Other materials: Some high-end wave ceiling aluminum veneers also use other materials for decoration, such as glass, stone, etc., to increase the decorative effect.

2、 Quality assessment

1. Strength: The strength of the corrugated ceiling aluminum veneer is one of the important indicators for evaluating its quality. Aluminum veneers with higher strength can withstand greater loads and pressures, making them more durable.

2. Corrosion resistance: The corrugated ceiling aluminum veneer needs to be frequently exposed to outdoor environments, so it needs to have good corrosion resistance. The corrosion resistance of aluminum veneer can be evaluated through methods such as salt spray testing.

3. Flatness: The flatness of the corrugated ceiling aluminum veneer has a significant impact on its appearance and installation quality. The quality of aluminum veneer can be evaluated by measuring its surface flatness.

4. Color uniformity: The color uniformity of the corrugated ceiling aluminum veneer is also an important indicator for evaluating its quality. The color uniformity can be evaluated by comparing the color differences between different aluminum veneers.

5. Fire resistance: The corrugated ceiling aluminum veneer needs to have good fire resistance to ensure the safety of the building. The fire resistance of aluminum veneer can be evaluated by conducting combustion tests and other methods.

3、 Summary

The material selection and quality evaluation of corrugated ceiling aluminum panels are of great significance for ensuring the beauty and comfort of indoor environments. When choosing wave suspended aluminum veneer, suitable materials should be selected according to actual needs; When evaluating the quality of corrugated ceiling aluminum veneer, a comprehensive evaluation should be conducted from the aspects of strength, corrosion resistance, flatness, color uniformity, and fire resistance. Through reasonable material selection and quality evaluation, better decorative effects and user experience can be brought to indoor environments.

Customer service QQ

Customer service QQ