Industry information

Company News

- Craftsmanship in Curtain Wall Aluminum Veneer: Creating a New Height in Architectural Aesthetics!

- Imitation wood grain aluminum veneer: a work of art that blends modernity and tradition

- Wood grain aluminum veneer, a fashionable choice for modern architecture

- Wood grain aluminum veneer: a harmonious symphony of aluminum and nature

- Customized aluminum veneer to make the building more contemporary

Industry dynamics

- Hyperbolic ceiling aluminum veneer creates a new era of beautiful living

- The unique charm of wood grain aluminum veneer, a new trend in home decoration

- Aluminum veneer: the fashionable choice for modern architecture, your good home partner?

- Exploration of the application of curtain wall aluminum square tube in architecture

- Wood grain aluminum veneer, a fashionable "texture" choice for modern architecture

Frequently asked questions

- What are the limitations of the application scope of aluminum veneer?

- Can the insulation function of aluminum veneer improve the comfort of buildings?

- Is the surface treatment method of aluminum veneer restricted?

- Can aluminum veneer be used for building platform design?

- How to evaluate the impact of the plasticity of aluminum veneer on the appearance of buildings?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Color matching and matching techniques for 1.5mm aluminum veneer

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: March 11, 2025 00:42:56

- Click:0

1.5mmAluminum veneerIt is a very common building material, and its color matching and matching techniques are of great significance in ensuring the aesthetics and practicality of buildings. This article will provide a detailed introduction to the color matching and matching techniques of 1.5mm aluminum veneer.

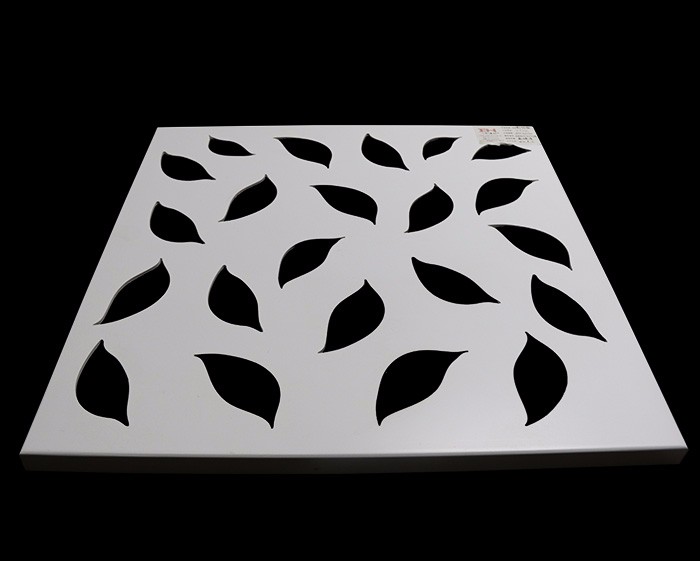

In terms of material properties, 1.5mm thick aluminum veneer typically has certain color selection and surface treatment capabilities. This is because the main component of aluminum veneer is aluminum alloy, which has good plasticity and surface treatment ability, and can be colored and surface treated according to needs. The surface of aluminum veneer can also be treated with some special techniques, such as anodizing, spraying, etc., to further improve its surface quality and decorative effect.

In terms of color matching, multiple factors need to be considered, including the design style of the building, indoor and outdoor environment, and functional use. Generally speaking, the colors of aluminum veneer can be divided into the following categories:

1. Classic white: suitable for large-scale decoration and covering of the exterior walls, roofs, and other areas of most buildings.

2. Fashionable gray: suitable for large-scale decoration and covering of modern style buildings such as exterior walls and roofs.

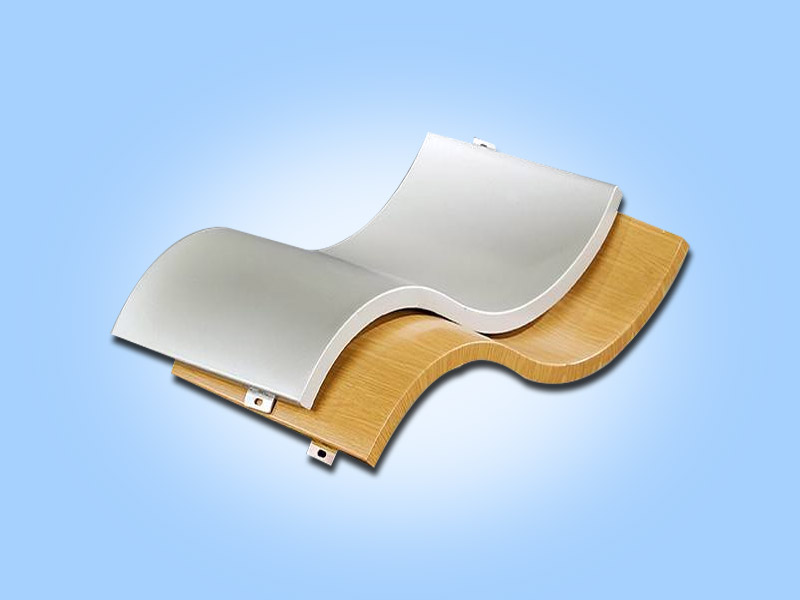

3. Natural wood grain: Suitable for ecological and environmentally friendly buildings and interior decoration, it can create a natural and warm atmosphere.

4. Bright red: Suitable for commercial buildings, event venues, and other places that require highlighting personality and vitality.

You can also choose different color combinations and matching methods according to specific needs, such as:

1. Same color scheme matching: Matching aluminum veneers of different colors according to the same color scheme can create a coordinated and unified visual effect.

2. Contrastive color matching: Matching aluminum veneers of different colors according to contrasting colors can create a vivid and lively visual effect.

In terms of quality inspection and acceptance, it is also necessary to check and evaluate the color matching of aluminum veneer. During this process, it is necessary to pay attention to factors such as the dimensional accuracy, surface smoothness, and color uniformity of the aluminum veneer to ensure that its color matching meets the requirements.

The color matching and matching skills of 1.5mm thick aluminum veneer are one of its very important advantages. In practical applications, attention should be paid to the quality and effect of the selected materials to ensure better decorative and usage effects. At the same time, attention should also be paid to the color selection, surface treatment ability, and construction details of the materials.

Customer service QQ

Customer service QQ