Industry information

Company News

- Imitation wood grain aluminum veneer: the green "skin" of modern architecture

- Aluminum veneer customization, creating a new trend of personalized space

- Aluminum veneer: not just decoration, but also the soul of architecture

- Aluminum veneer customization, creating a new trend of personalized space

- Imitation wood grain aluminum veneer: a new high-end aluminum material, a perfect encounter between classical and modern styles

Industry dynamics

- What is the price of fluorocarbon aluminum veneer?

- Wood grain aluminum veneer: a fashionable choice for modern architecture

- Installation skills of aluminum veneer for exterior wall ceiling

- Market prospects and development trends of indoor stone patterned aluminum veneer

- Imitation wood grain aluminum veneer: a retro trend in modern architecture

Frequently asked questions

- Can the insulation function of aluminum veneer improve the comfort of buildings?

- Can aluminum veneer be applied to the exterior design of high-rise buildings?

- Does the production of aluminum veneer require certification?

- Will the thickness of aluminum veneer affect its service life?

- How to evaluate the impact of the plasticity of aluminum veneer on the appearance of buildings?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Introduction to bending processing technology of 1.5mm aluminum veneer

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: March 14, 2025 21:44:56

- Click:0

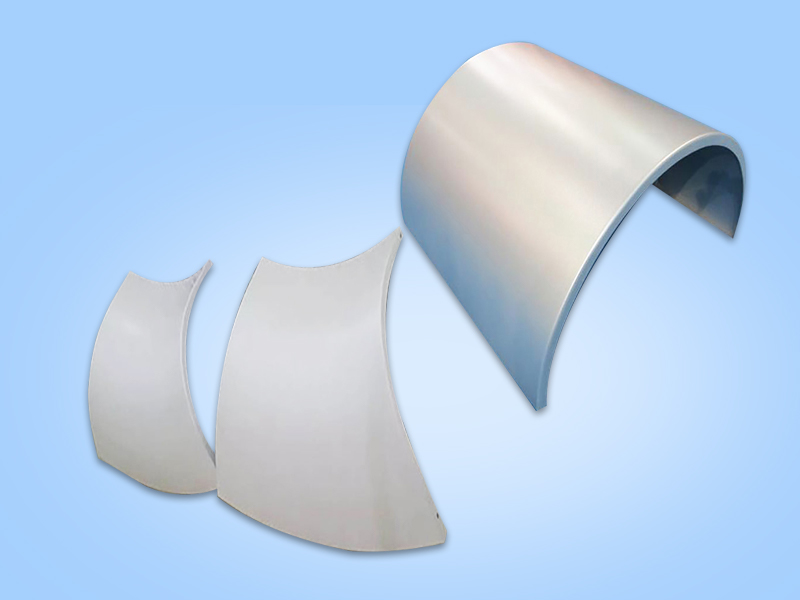

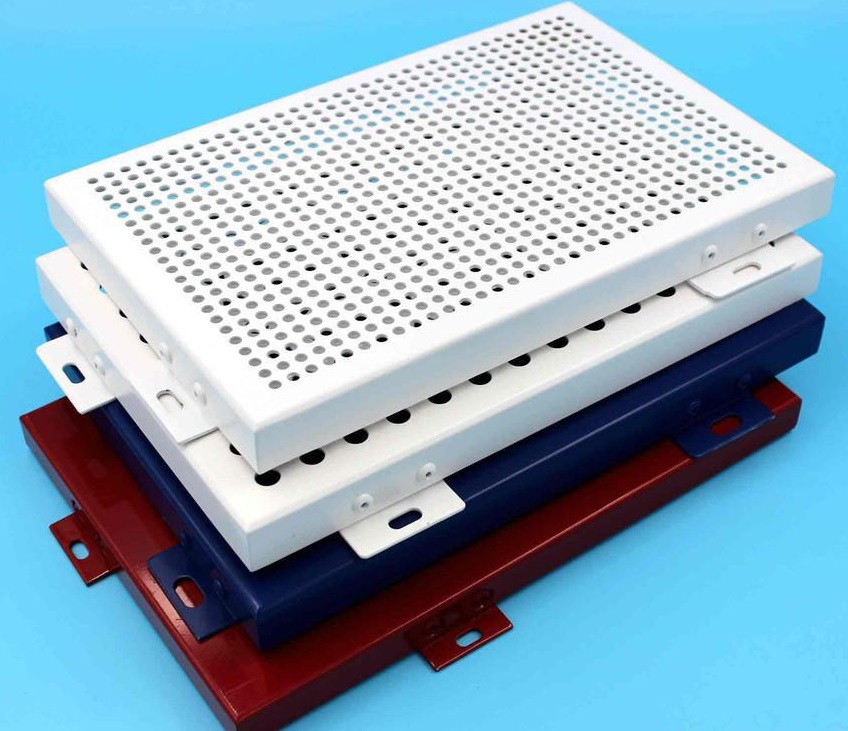

1.5mmAluminum veneerIt is a common building material, and its bending processing technology has a significant impact on its decorative effect and performance. This article will provide a detailed introduction to the bending processing technology of 1.5mm aluminum veneer.

In terms of material properties, 1.5mm thick aluminum veneer usually has good plasticity and ductility, and can adapt to certain bending angles and shapes. When performing bending processing, the following aspects should be noted:

1. Choose the appropriate bending equipment: Bending equipment is a key tool for achieving aluminum veneer bending processing. Common bending equipment includes manual bending machines, hydraulic bending machines, CNC bending machines, etc. Different devices are suitable for different types of aluminum veneers and different bending angles and shapes.

2. Determine the bending angle and shape: Before performing bending processing, it is necessary to determine the bending angle and shape of the aluminum veneer according to the design requirements and actual situation. Generally speaking, the bending angle of aluminum veneer should not exceed 90 degrees, otherwise it will affect its service life and decorative effect. Attention should also be paid to whether the shape of the aluminum veneer meets the design requirements.

3. Pay attention to the protection of aluminum veneer: When bending, it is necessary to pay attention to the protection of aluminum veneer. Firstly, it is necessary to clean and treat the surface of the aluminum veneer to avoid scratching or damaging the surface during the processing. Protective measures need to be installed around the aluminum veneer to prevent accidental injuries during processing.

4. Ensure machining accuracy and quality: When performing bending machining, it is necessary to ensure machining accuracy and quality. This requires the selection of appropriate tools and fixtures, as well as precise adjustment and control. Attention should also be paid to the influence of factors such as temperature and humidity during the processing to avoid damage to the aluminum veneer.

The bending processing technology of 1.5mm thick aluminum veneer requires comprehensive consideration of multiple factors, including material characteristics, equipment selection, processing accuracy, etc. In practical applications, appropriate bending processing techniques and methods should be selected according to specific situations to achieve the best results and usability.

Customer service QQ

Customer service QQ