Industry information

Company News

- Aluminum veneer customization: an artistic journey to create personalized spaces

- Aluminum veneer: the fashionable outerwear of modern architecture

- Aluminum veneer customization, creating a new trend of personalized space

- Unveiling the 'Curtain Wall Aluminum Veneer': The Hidden Guardian of the Architecture Industry

- Imitation wood grain aluminum veneer: the new favorite of modern architecture, the perfect integration of nature and technology

Industry dynamics

- Hyperbolic shaped aluminum material creates a new benchmark for modern architecture

- Discussion on the application of painted aluminum veneer for door heads in architectural design

- Aluminum veneer: not just a building material, but also a fusion of art and technology

- Application scope and effect display of carved wall aluminum veneer

- What is the innovative value of aluminum veneer in architectural exterior design?

Frequently asked questions

- Can aluminum veneer be used for building platform design?

- How to evaluate the impact of the plasticity of aluminum veneer on the appearance of buildings?

- Does the production of aluminum veneer require certification?

- Can the insulation function of aluminum veneer improve the comfort of buildings?

- Can aluminum veneer be applied to the exterior design of high-rise buildings?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Quality and process analysis of perforated aluminum veneer for exterior walls

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: February 23, 2025 19:31:41

- Click:0

With the continuous development of the architectural decoration industry, exterior wall decoration materials are becoming increasingly diverse. And punching holes on the exterior wallAluminum veneerAs a new type of building material, it is highly favored in exterior wall decoration. Its unique punching design and advantages such as lightweight and high strength have made it a new trend in modern architecture. However, how to ensure the quality and craftsmanship of perforated aluminum veneer for exterior walls? Below, we will provide a detailed introduction to the quality and craftsmanship of perforated aluminum veneer for exterior walls.

1、 Material selection

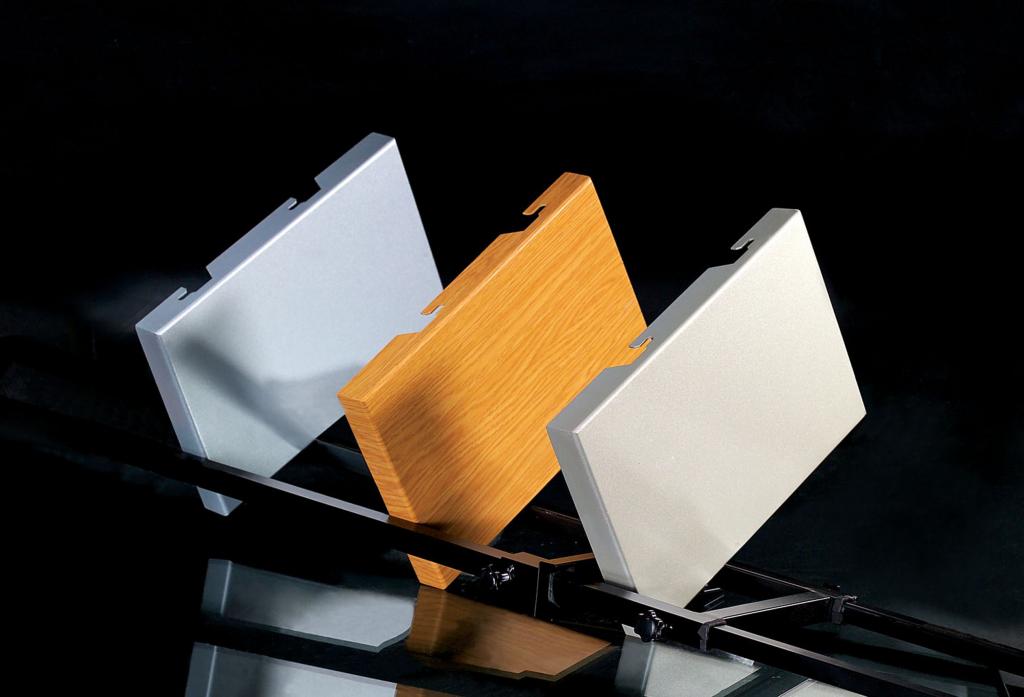

1. Aluminum alloy material

The main material used for perforated aluminum veneer on exterior walls is aluminum alloy, which has the characteristics of lightweight and high strength, and can reduce the weight of buildings, energy consumption, and costs. Aluminum alloy also has good corrosion resistance and weather resistance, which can ensure the service life and aesthetics of perforated aluminum veneer for exterior walls.

2. Polyester coating

The surface of perforated aluminum veneer for exterior walls is usually treated with polyester coating, which has excellent weather resistance, corrosion resistance, and wear resistance, and can effectively protect the surface of aluminum veneer from oxidation, corrosion, and wear. Polyester coating can also enhance the aesthetics and texture of aluminum veneer.

2、 Process flow

1. Numerical Control Machining

The perforated aluminum veneer for exterior walls is processed and formed by CNC machine tools, which have the characteristics of high precision and fast speed. Numerical control machining can ensure the dimensional accuracy and shape accuracy of aluminum veneer, thereby ensuring the quality and stability of aluminum veneer.

2. Punching design

The perforated aluminum veneer on the exterior wall enhances its aesthetics and breathability through punching design. The design of punching can be customized according to different needs, such as personalized design in terms of size, shape, etc. Punching can also increase the transparency and ventilation of buildings, making indoor spaces more comfortable and healthy.

3. Coating treatment

The surface of perforated aluminum veneer for exterior walls is usually treated with polyester coating, which has excellent weather resistance, corrosion resistance, and wear resistance, and can effectively protect the surface of aluminum veneer from oxidation, corrosion, and wear. Coating can also enhance the aesthetics and texture of aluminum veneer.

3、 Quality control

1. Raw material inspection

The raw materials of perforated aluminum veneer for exterior walls need to undergo strict inspection and screening to ensure that they meet national standards and customer requirements. Only products that have passed the raw material inspection can proceed to the next process.

2. Production process control

The production process of perforated aluminum veneer for exterior walls requires strict control and management to ensure product quality and stability. During the production process, it is necessary to monitor and detect every step, and promptly address any issues.

3. Finished product inspection

The finished products of perforated aluminum veneer for exterior walls need to undergo comprehensive inspection and testing to ensure compliance with national standards and customer requirements. Only products that have passed the finished product inspection can be delivered to customers for use.

4、 Summary

Through the analysis of the quality and process of perforated aluminum veneer for exterior walls, it can be seen that ensuring the quality and process of perforated aluminum veneer for exterior walls requires consideration and control from multiple aspects such as material selection, process flow, and quality control. Only in this way can the quality and stability of the perforated aluminum veneer on the exterior wall be guaranteed, creating a better and healthier living environment for people.

Customer service QQ

Customer service QQ