Industry information

Company News

- Aluminum veneer customization, creating personalized space and new fashion

- Aluminum veneer curtain wall: a perfect fusion of architectural aesthetics and practicality

- The Charm of Aluminum Veneer: Fashion Elements in Modern Architecture

- Wood grain aluminum veneer: a unique natural beauty in modern architecture

- Aluminum veneer customization, creating a new trend of personalized space

Industry dynamics

- Personalized customized aluminum veneer creates a unique suspended ceiling

- Industry standard for aluminum veneer prices

- Analyze the sales strategy of aluminum veneer

- Irregular shaped ceiling aluminum veneer - Innovative design creates unique space

- Wood grain aluminum veneer: a perfect fusion of nature and modernity

Frequently asked questions

- Will the thickness of aluminum veneer affect its service life?

- Can aluminum veneer be applied to the exterior design of high-rise buildings?

- How does aluminum veneer provide the wind resistance required for modern buildings?

- What are the types of aluminum veneer?

- Does the production of aluminum veneer require certification?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Hyperbolic shaped aluminum material creates a new benchmark for modern architecture

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: February 23, 2025 15:21:37

- Click:0

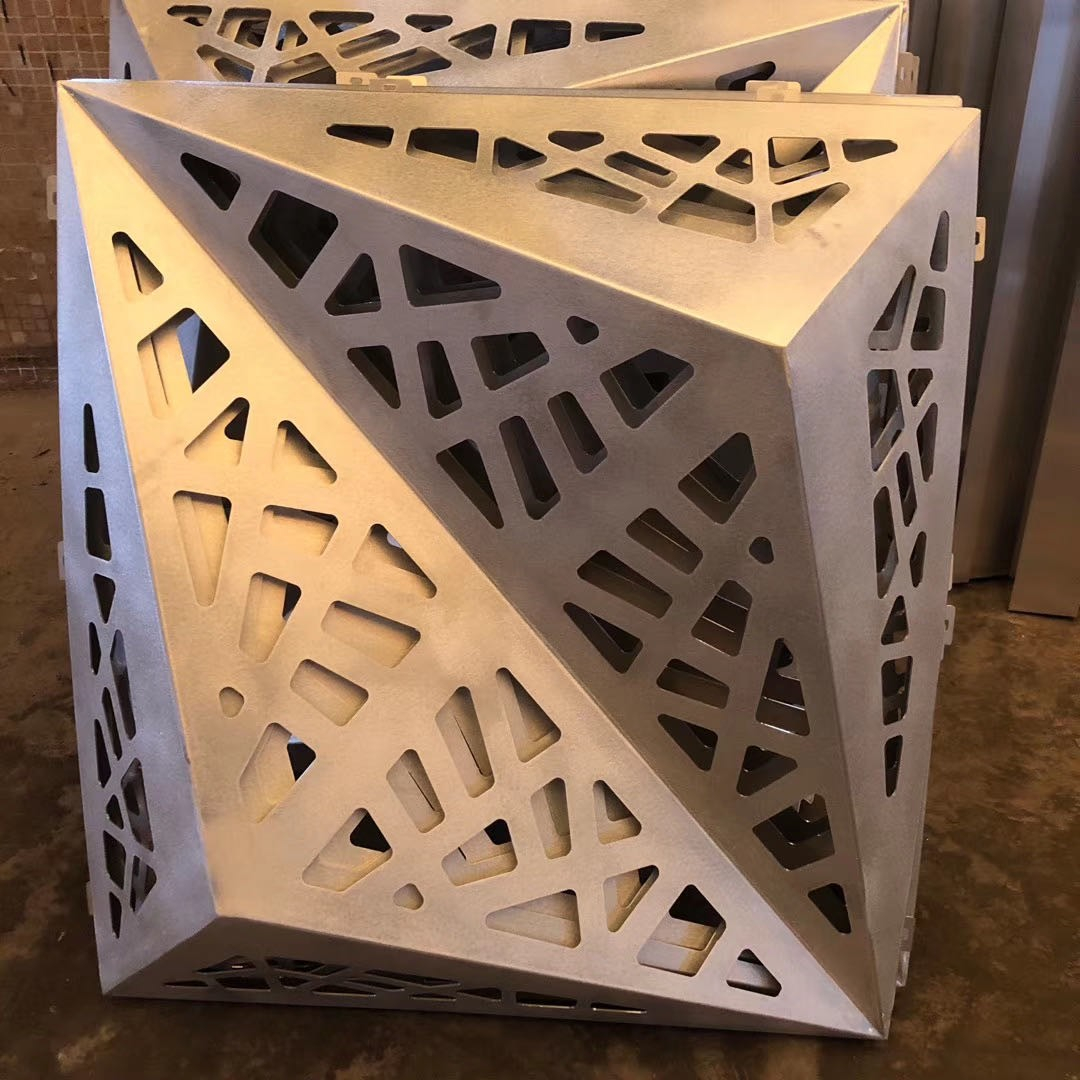

With the development of modern architecture, people's requirements for building materials are also increasing. Traditional building materials are no longer able to meet people's demands for both aesthetics and practicality in architecture. Among numerous new materials, hyperbolic shaped aluminum materials are rapidly rising and becoming a new benchmark for modern architecture.

1、 Characteristic Introduction

1. Unique styling design

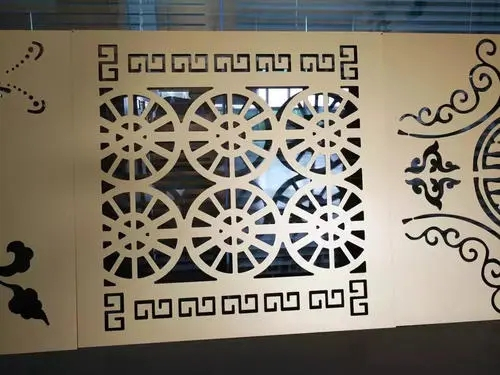

The hyperbolic shaped aluminum material adopts a double curved surface design, which can present more beautiful lines and curves, increasing the artistic sense and personalization of the building. This design can also better adapt to the structure and shape of buildings, improving overall stability and safety.

2. Lightweight and high-strength

Compared to traditional flat materials, hyperbolic shaped aluminum materials have higher strength and stiffness, as well as lighter weight, making them easier to handle and install. This makes hyperbolic shaped aluminum materials more advantageous in some situations where high load-bearing requirements are needed.

3. Strong corrosion resistance

After anodizing treatment, the hyperbolic shaped aluminum material forms a layer of oxide film on the surface, which has strong oxidation resistance and weather resistance. This processing method can extend the service life of the material and make it more aesthetically pleasing and durable.

2、 Application Fields

1. Interior decoration

Hyperbolic shaped aluminum materials can be widely used in interior decoration, such as ceilings, walls, partitions, etc. By using different processing and surface treatment methods, various styles and effects can be created to meet the needs of different occasions.

2. Outdoor decoration

In addition to indoor decoration, hyperbolic shaped aluminum materials can also be used in outdoor decoration, such as curtain walls, roofs, etc. This material has good waterproof and fireproof properties, which can effectively protect the safety of the internal structure and facilities of buildings.

3. Other application scenarios

In addition to the above two aspects, hyperbolic shaped aluminum materials can also be applied to other occasions, such as commercial squares, sports venues, airports, etc. These occasions have high requirements for the appearance and practicality of buildings, and hyperbolic shaped aluminum materials can precisely meet these requirements, adding uniqueness and artistic sense to these occasions.

3、 Key points of production process and technology

1. Raw material preparation

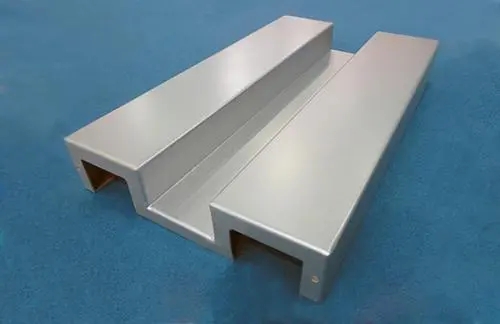

The main raw material for hyperbolic shaped aluminum materials is aluminum alloy plates, which require processing such as cutting, bending, and punching. In the process of preparing raw materials, it is necessary to pay attention to the quality and specifications of the materials to ensure that they meet the design requirements.

2. Surface treatment

The surface of hyperbolic shaped aluminum material needs special treatment to increase its oxidation resistance and weather resistance. Common surface treatment methods include anodizing, electrophoretic coating, etc. These methods can makeAluminum veneerA layer of oxide film or coating is formed on the surface to improve its hardness and wear resistance.

3. Forming and processing

After surface treatment, it is necessary to shape the hyperbolic shaped aluminum material. Common forming processing methods include cutting, bending, stamping, etc. Through these processing methods, aluminum veneer can be made into the desired shape and size.

4. Welding and assembly

After the molding process, it is necessary to weld and assemble the hyperbolic shaped aluminum material. Common welding methods include spot welding, seam welding, etc. Aluminum veneer can be assembled into a whole through welding, ensuring the strength and sealing of its connections.

4、 Summary and Prospect

With the increasing demand for architectural decoration, hyperbolic shaped aluminum materials are rapidly emerging as a new type of material and receiving widespread attention. It has unique styling design, lightweight high strength, and strong corrosion resistance, which can meet the needs of different occasions. In the future, with the continuous advancement of technology and the expansion of application fields, hyperbolic shaped aluminum materials are expected to become a new benchmark for modern architecture.

Customer service QQ

Customer service QQ