Industry information

Company News

- Aluminum veneer: improving the fire resistance of buildings

- Aluminum veneer curtain wall, perfect integration of architectural aesthetics and technology

- Aluminum veneer curtain wall, the fashionable coat of architecture

- Aluminum veneer curtain wall: the "fashionable coat" of modern architecture

- Aluminum veneer customization: an artistic journey to create personalized spaces

Industry dynamics

- Aluminum veneer curtain wall: the fashionable coat of modern architecture

- Customized aluminum veneer, creating a new trend of personalized space

- Detailed explanation of aluminum veneer installation process

- Aluminum veneer curtain wall: the fashionable coat of modern architecture

- Aluminum veneer: the new darling of architectural aesthetics

Frequently asked questions

- Can aluminum veneer be used for building platform design?

- How to evaluate the impact of the plasticity of aluminum veneer on the appearance of buildings?

- What are the types of aluminum veneer?

- Can the insulation function of aluminum veneer improve the comfort of buildings?

- Is the surface treatment method of aluminum veneer restricted?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

How to choose suitable fluorocarbon aluminum veneer for buildings?

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: March 19, 2025 03:02:18

- Click:0

Building fluorocarbonAluminum veneerIt is a high-end decorative material with numerous advantages and characteristics. When choosing a suitable fluorocarbon aluminum veneer for construction, multiple factors need to be considered, such as decorative effect, durability, environmental friendliness, sound insulation, thermal insulation performance, etc. This article will provide a detailed introduction on how to choose suitable fluorocarbon aluminum veneers for construction.

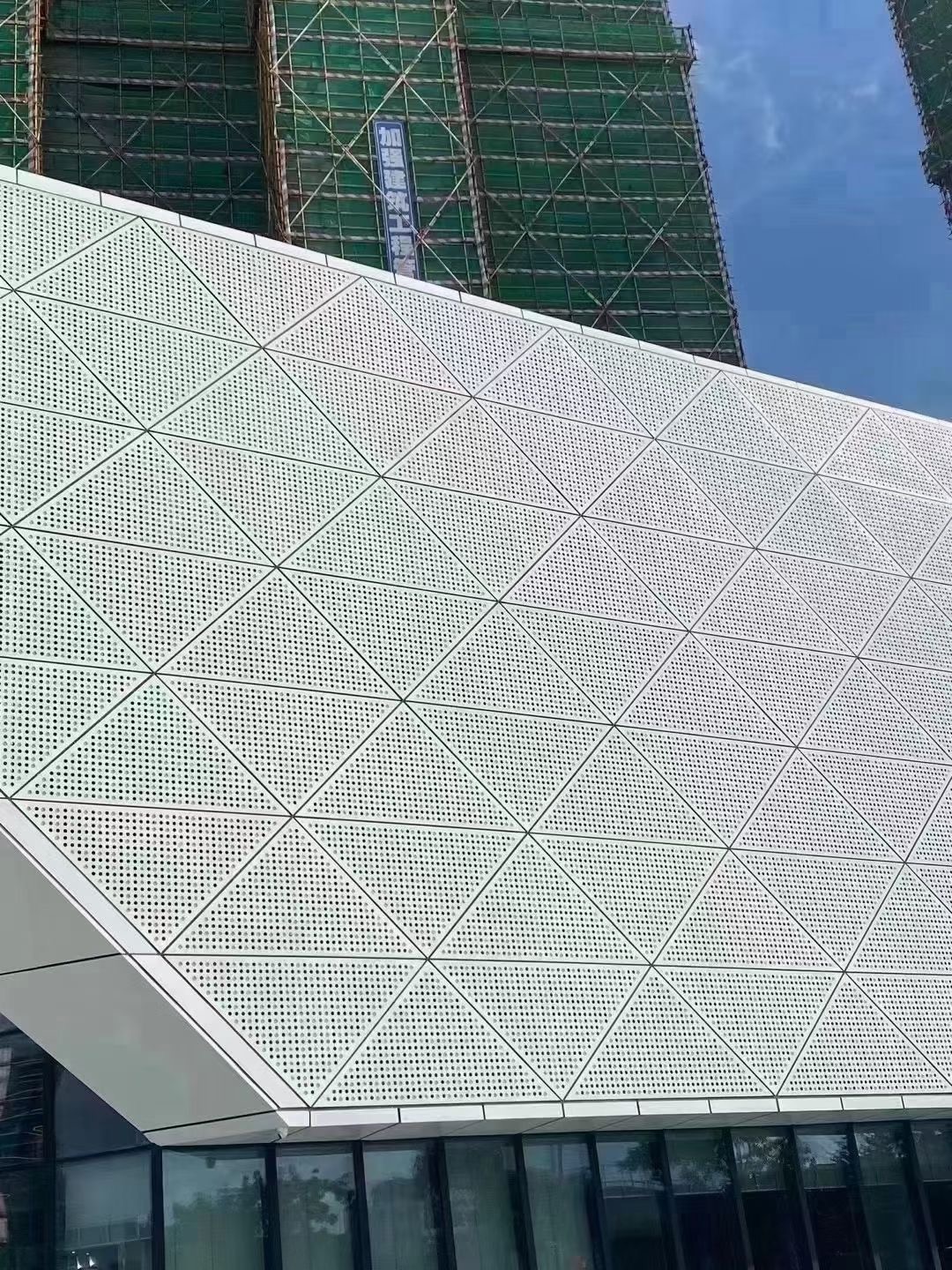

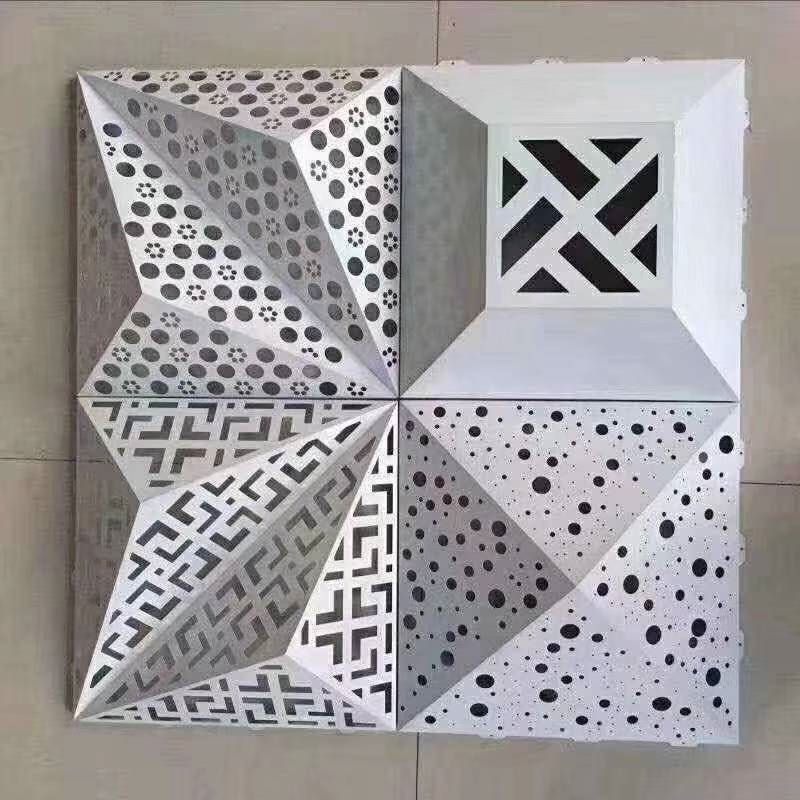

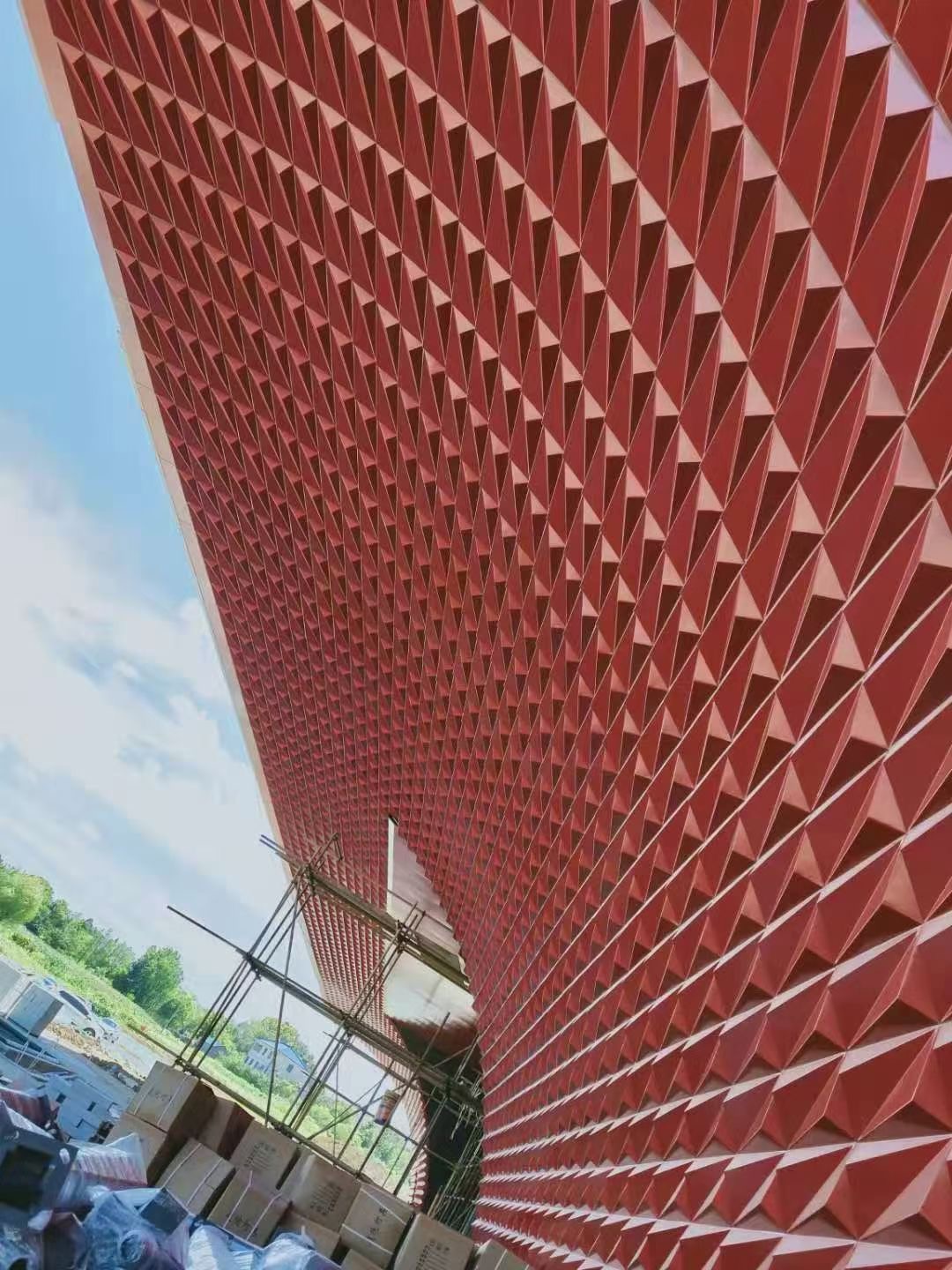

We need to consider the decorative effect. The surface of fluorocarbon aluminum veneer is specially treated to form various colors and patterns, such as wood grain, stone grain, patterns, etc., which can meet the decoration needs of different places. When choosing fluorocarbon aluminum veneer, one can choose the appropriate color and pattern based on actual needs and design style to achieve the best decorative effect.

Durability needs to be considered. Fluorocarbon aluminum veneer is made of high-strength aluminum alloy material, which can form a hard oxide film through special surface treatment process, and has good wear resistance, corrosion resistance, and weather resistance. When choosing fluorocarbon aluminum veneer, it is advisable to choose products with higher hardness and strength, and ensure good surface treatment quality to extend their service life.

Again, environmental friendliness needs to be considered. Fluorocarbon aluminum veneer is made of 100% renewable resource aluminum material, which does not produce harmful gases and waste residue during the production process, and has a relatively small impact on the environment. When choosing fluorocarbon aluminum veneer, it is possible to choose products that meet environmental standards and ensure that the manufacturer has relevant certifications and qualifications.

Sound insulation and thermal insulation performance need to be considered. After anodizing and other treatments, a dense oxide film can be formed on the surface of fluorocarbon aluminum veneer, which can effectively prevent heat transfer and improve the thermal insulation performance of buildings. Fluorocarbon aluminum veneer can also have a certain sound insulation effect, which can improve the comfort of buildings. When choosing fluorocarbon aluminum veneer, products with good sound insulation and thermal insulation performance can be selected.

Choosing a suitable fluorocarbon aluminum veneer for construction requires comprehensive consideration of multiple factors, such as decorative effect, durability, environmental friendliness, sound insulation, thermal insulation performance, etc. Only by comprehensively considering and comparing based on actual needs and design styles can one choose the most suitable product for oneself.

Customer service QQ

Customer service QQ