Industry information

Company News

- Unveiling the Charm of Aluminum Veneer: The 'Fashion Coat' of Modern Architecture

- Aluminum veneer: the "fashionable coat" of modern architecture

- Imitation wood grain aluminum veneer: a perfect fusion of modernity and nature

- Wood grain aluminum veneer: a harmonious symphony of aluminum and nature

- Curtain wall aluminum veneer: an innovative tool for architectural aesthetics

Industry dynamics

- New trend of aluminum plate: the unique charm of imitation wood grain aluminum veneer

- Aluminum veneer: the "fashionable coat" of modern architecture

- Evaluation of Antifreeze and Crack Prevention Performance of Aluminum Single Panel for Curtain Wall

- Imitation wood grain aluminum veneer: a perfect encounter between modernity and nature

- Have you noticed that many buildings have 'silver coats' on their exterior walls? This is not

Frequently asked questions

- Will the thickness of aluminum veneer affect its service life?

- What are the limitations of the application scope of aluminum veneer?

- How to evaluate the impact of the plasticity of aluminum veneer on the appearance of buildings?

- Can aluminum veneer be applied to the exterior design of high-rise buildings?

- What are the types of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Production process and quality control methods for curtain wall aluminum panels

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: February 28, 2025 17:32:06

- Click:0

Curtain wall aluminum plate is a new type of building decoration material, which has the advantages of light weight, high strength, corrosion resistance, etc. It also has good thermal insulation and thermal insulation performance, strong customizability, and convenient and fast construction. The production process and quality control methods are crucial for ensuring the quality and stability of the product. Below, we will provide a detailed introduction to the production process and quality control methods of curtain wall aluminum panels.

1、 Production process

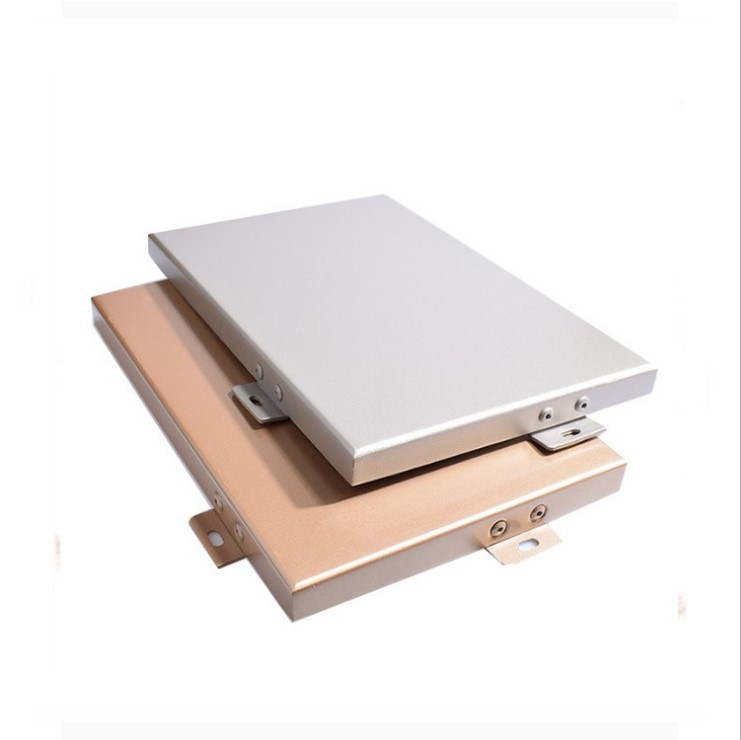

1. Raw material preparation: The main raw material for curtain wall aluminum panels is aluminum alloy panels, which require strict quality inspection and screening. Different auxiliary materials and additives need to be added according to different design requirements.

2. Cutting and processing: Cut and process raw materials according to design requirements to obtain the desired size and shape. During the cutting process, it is important to avoid issues such as scratches and cracks.

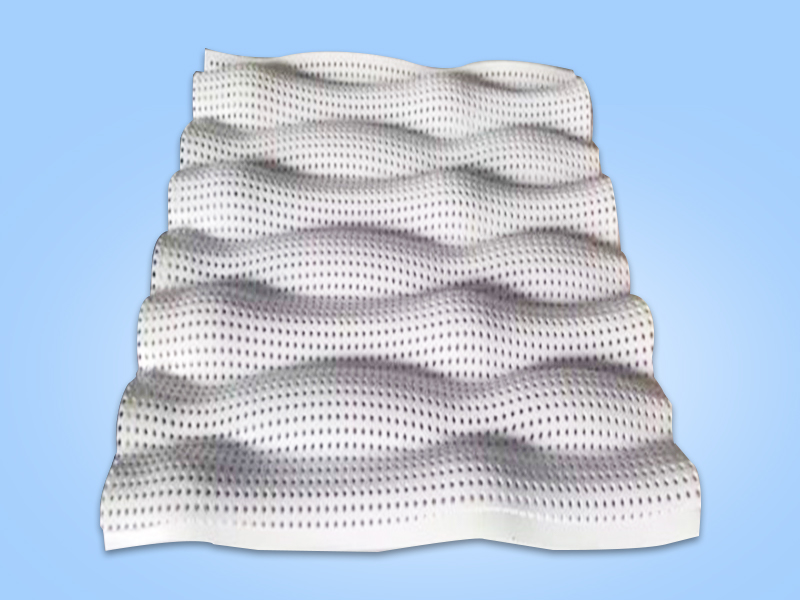

3. Surface treatment: Surface treatment of the cut curtain wall aluminum plate, including anodizing, electrophoretic coating, spraying, etc., to improve its corrosion resistance and aesthetics.

4. Assembly and installation: Combine and assemble curtain wall aluminum panels of different colors and shapes, and install them using professional installation tools and techniques to ensure their stability and safety.

2、 Quality control methods

1. Raw material inspection: During the production process, strict inspection and screening of raw materials are required to ensure that their quality meets the requirements.

2. Production process control: In the production process, it is necessary to strictly control and manage every link to avoid quality problems.

3. Finished product inspection: After production is completed, strict inspection and testing of the finished product are required to ensure that its quality meets standards and requirements.

4. After sales service: After sales, it is necessary to provide professional after-sales service, timely solve customer problems and feedback information, in order to improve customer satisfaction and trust.

3、 Case sharing

Let's take a look at a case study of the production process and quality control methods of curtain wall aluminum panels: a company undertook a large-scale commercial center curtain wall aluminum panel production project. The company has adopted advanced production processes and strict quality control methods, conducting comprehensive inspections and tests from raw material procurement to finished product delivery, and ultimately completing a high-quality curtain wall aluminum panel production project. The exterior walls of the commercial center present a unique artistic style and modern atmosphere, attracting numerous customers to visit and shop. This fully demonstrates the importance and role of the production process and quality control methods of curtain wall aluminum panels in building exterior decoration.

4、 Summary

The production process and quality control methods of curtain wall aluminum panels are crucial for ensuring product quality and stability. With the continuous advancement and innovation of technology in the future, we believe that curtain wall aluminum panels will be more widely used and developed. It also requires practitioners in the construction and decoration industry to constantly learn and explore in order to adapt to market demands and changes.

Customer service QQ

Customer service QQ