Industry information

Company News

- Aluminum veneer: not just a sheet, but also a fashion ambassador

- Wood grain aluminum veneer, the new darling of modern architecture!

- Exploring the Charm and Secrets of Aluminum Veneers in Curtain Walls

- Imitation wood grain aluminum veneer: a work of art that blends modernity and tradition

- Aluminum veneer: a fashionable element in modern architecture

Industry dynamics

- Analysis of Material, Process, and Application of Aluminum Veneer for Painted Ceiling

- Imitation wood grain aluminum veneer: a harmonious symphony of modernity and nature

- How to choose the material suitable for aluminum alloy air conditioning protective cover?

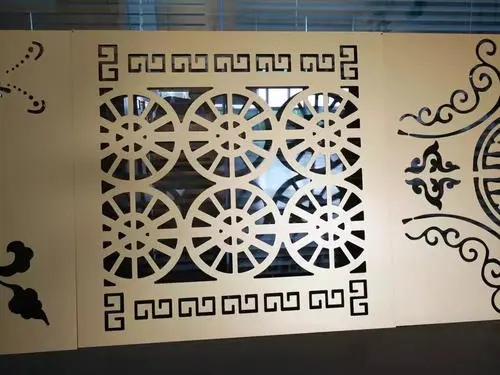

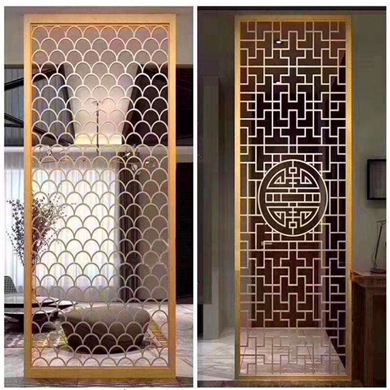

- The anti-corrosion performance and environmental characteristics of carved painted aluminum veneer

- How does aluminum veneer perform in outdoor environments?

Frequently asked questions

- Can aluminum veneer be applied to the exterior design of high-rise buildings?

- Does the production of aluminum veneer require certification?

- Will the thickness of aluminum veneer affect its service life?

- How does aluminum veneer provide the wind resistance required for modern buildings?

- Can aluminum veneer be used for building platform design?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

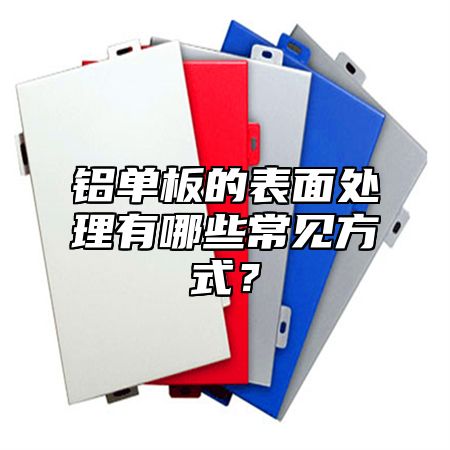

What are the common methods for surface treatment of aluminum veneer?

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: 2022-03-09 05:08:22

- Click:0

Aluminum veneerIt is a common building material with advantages such as lightweight, corrosion resistance, and easy processing. In the production and manufacturing process of aluminum veneer, surface treatment is one of the important links to improve its performance and quality. The commonly used surface treatment methods include spraying, rolling, anodizing, etc. Below, we will provide a detailed introduction to the common surface treatment methods for aluminum veneer.

1、 Spray treatment

Spray coating treatment is the most commonly used method for surface treatment of aluminum veneer. Spraying treatment can improve the corrosion resistance and appearance quality of aluminum veneer, giving it a better decorative effect. In spray coating treatment, different coatings and process parameters can be used to achieve different decorative effects and anti-corrosion performance requirements. Generally speaking, spray coating treatment can be divided into various types such as powder coating, water-based coating, solvent based coating, etc.

2、 Roll processing

Roll pressing treatment is a surface treatment method of pressing aluminum veneer between two rollers. Rolling treatment can improve the wear resistance and corrosion resistance of aluminum veneer, as well as improve its surface smoothness and flatness. In roller pressing, it is necessary to select appropriate rollers and pressure to ensure that they meet the design and usage requirements.

3、 Anodizing treatment

Anodizing treatment is a surface treatment method that involves electrochemical oxidation of aluminum veneer in an electrolyte solution. Anodizing treatment can improve the corrosion resistance and hardness of aluminum veneer, as well as enhance its surface glossiness and color uniformity. In anodizing treatment, it is necessary to pay attention to controlling factors such as electrolyte concentration, temperature, and time to ensure that it meets design and usage requirements.

4、 Fluorocarbon spray treatment

Fluorocarbon spray treatment is a high-end surface treatment method for aluminum veneer. Fluorocarbon spraying treatment can improve the weather resistance and corrosion resistance of aluminum veneer, as well as enhance its surface glossiness and color uniformity. In fluorocarbon spraying treatment, it is necessary to select high-quality fluorocarbon coatings and process parameters to ensure that they meet design and usage requirements.

There are many surface treatment methods for aluminum veneer, each with its own characteristics and applicable scope. In practical applications, we need to comprehensively consider specific needs and requirements, and choose the most suitable surface treatment method to achieve the best use effect and economic benefits.

Customer service QQ

Customer service QQ