Industry information

Company News

- Aluminum veneer customization, creating the art of personalized space

- Aluminum veneer: the fashionable choice of modern architecture, revealing its charm!

- Imitation Wood Grain Aluminum Veneer: Natural Charm in Modern Architecture

- Aluminum veneer: the 'invisible hero' in architecture

- Imitation wood grain aluminum veneer: a retro trend in modern building materials

Industry dynamics

- Imitation wood grain aluminum veneer: a green choice for modern architecture

- Aluminum veneer customization makes buildings more artistic

- Aluminum veneer: a shining pearl in modern architecture

- Aluminum veneer: achieving a unique sense of form in architectural design

- Aluminum veneer customization, creating exclusive space and new fashion

Frequently asked questions

- Can the insulation function of aluminum veneer improve the comfort of buildings?

- How to evaluate the impact of the plasticity of aluminum veneer on the appearance of buildings?

- Is the surface treatment method of aluminum veneer restricted?

- What are the limitations of the application scope of aluminum veneer?

- How does aluminum veneer provide the wind resistance required for modern buildings?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Exquisite craftsmanship creates engineering carved aluminum veneer to showcase architectural quality and style

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: 2022-03-04 23:08:49

- Click:0

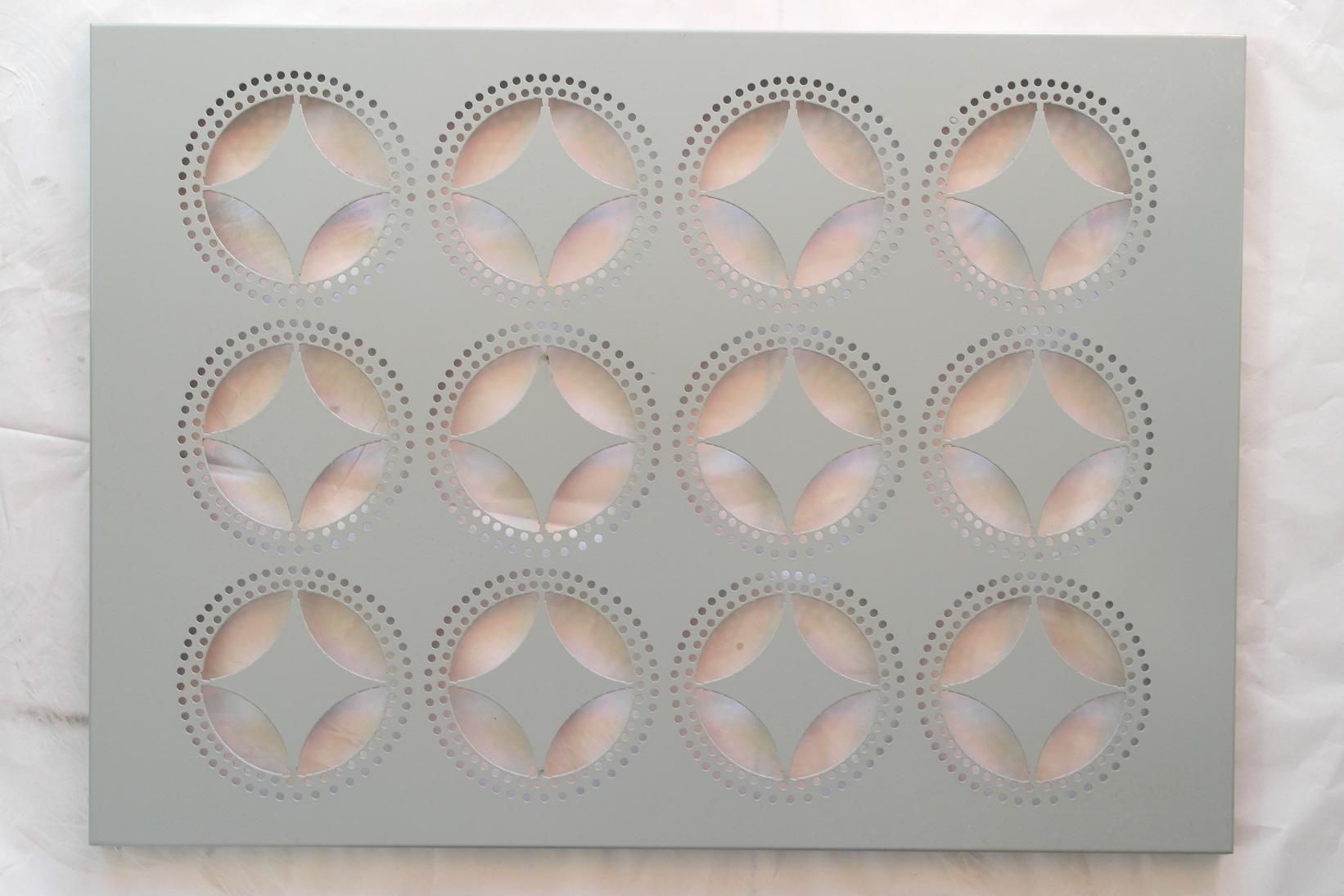

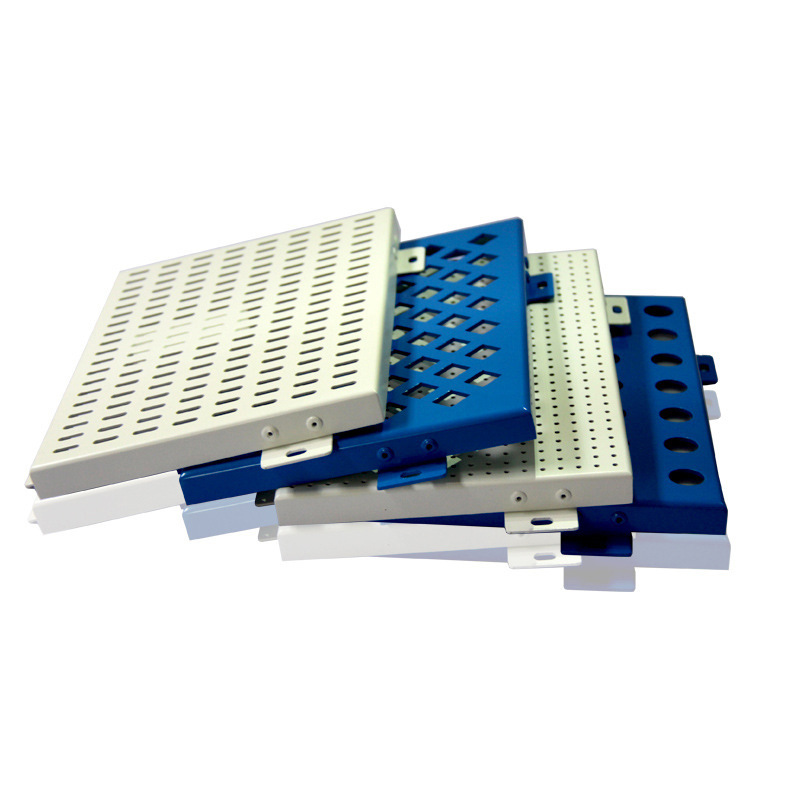

CarvingAluminum veneerIt is a common building material that has been widely used in modern architecture. With the increasing demand for architectural decoration, finely crafted engineering carved aluminum veneers have gradually become a popular choice in the market. This article will provide a detailed introduction to how finely crafted engineering carved aluminum veneers showcase architectural quality and style from the following aspects.

1、 Design concept

1. Putting people first: The design of finely crafted engineering carved aluminum veneer should be centered around people, emphasizing humanization and comfort, so that it can better adapt to different usage environments and functional requirements.

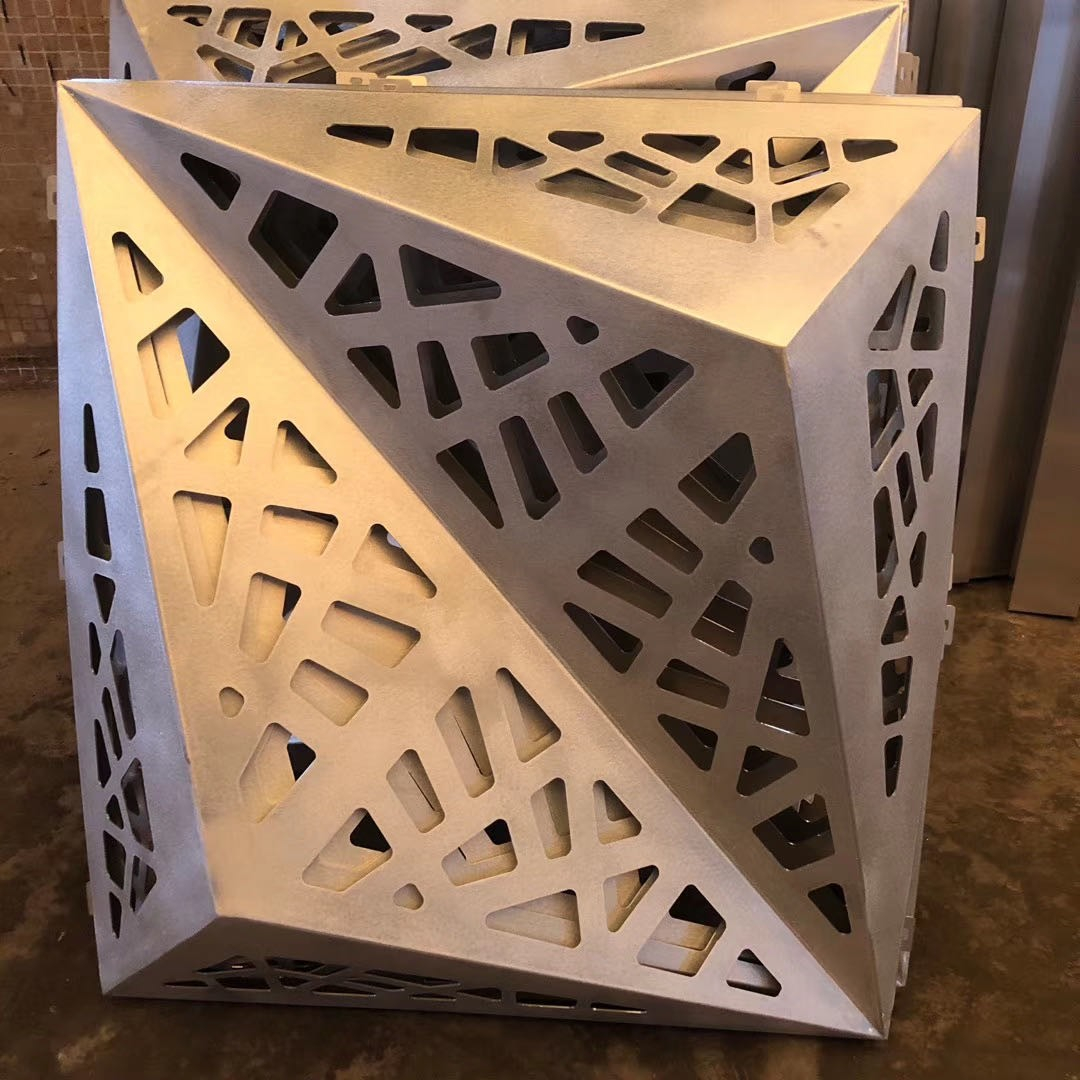

2. Innovative design: The design of finely crafted engineering carved aluminum veneer should be innovative and unique, and different shapes, colors, materials, and other elements can be combined to achieve better decorative effects and aesthetics.

2、 Craft production

1. High precision processing: The production of finely crafted engineering carved aluminum veneer requires the use of advanced processing equipment and technology to ensure its accuracy and quality.

2. Fine carving: The carving of engineering carved aluminum veneer created by fine craftsmanship requires multiple rounds of fine carving and polishing to present exquisite effects.

3、 Surface treatment

1. Anodizing treatment: Anodizing treatment can form a dense oxide film on the surface of aluminum veneer, improving its corrosion resistance and hardness.

2. Spray treatment: Spray treatment can form a uniform color coating on the surface of aluminum veneer, improving its decorative effect and aesthetics.

4、 Material selection

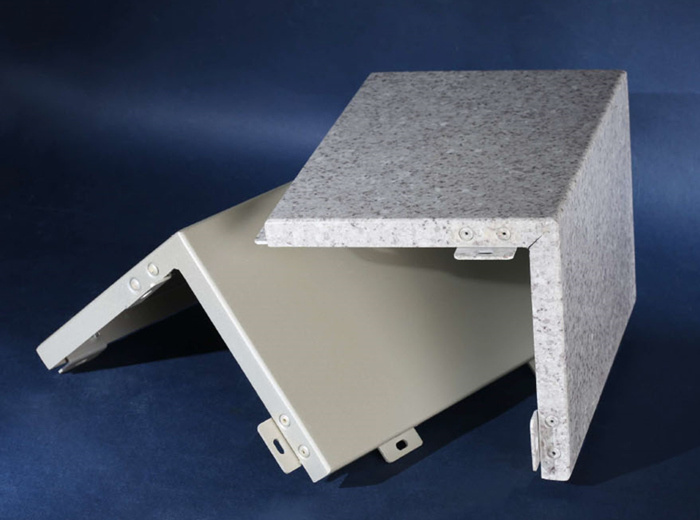

1. Aluminum alloy material: Aluminum alloy material has good strength and stiffness, can withstand large loads and external forces, ensuring the stability and safety of aluminum veneer.

2. High strength steel: High strength steel has high strength and hardness, can withstand greater loads and impact forces, and is suitable for large-scale engineering fields.

5、 Summary

The finely crafted engineering carved aluminum veneer is created through meticulous design, exquisite craftsmanship, fine surface treatment, and high-quality material selection. This type of building material can not only meet the different requirements of buildings, but also improve the overall aesthetics and practicality of buildings. In practical engineering, it is possible to choose finely crafted engineering carved aluminum veneers that are suitable for achieving better decorative and usage effects. Attention should also be paid to operating in accordance with relevant specifications and standards to ensure the quality and safety of the entire project.

Customer service QQ

Customer service QQ