Industry information

Company News

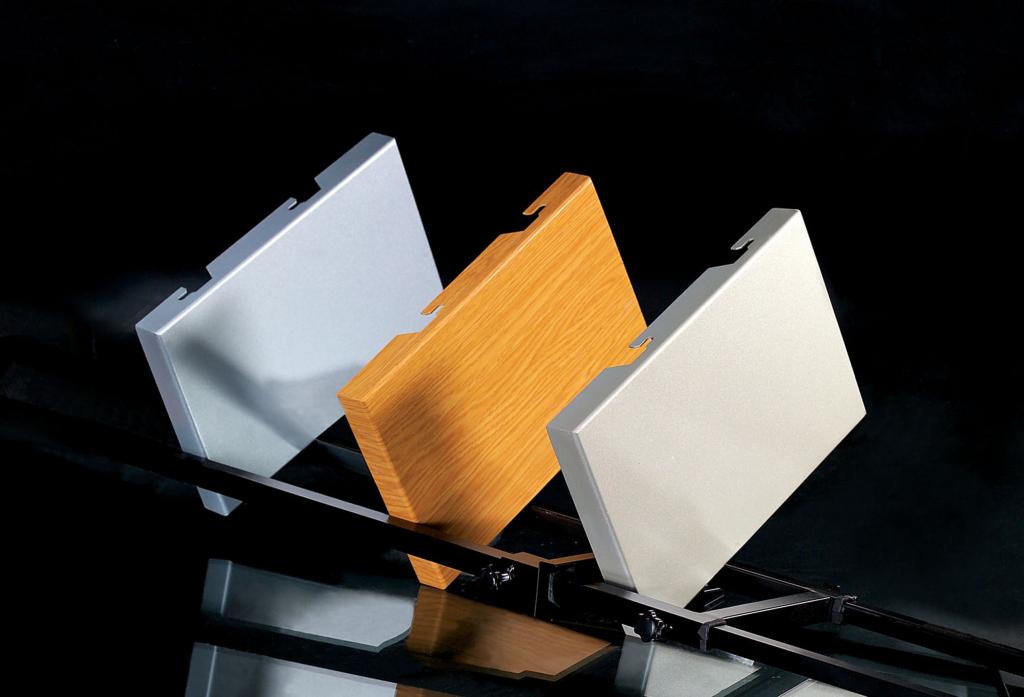

- Wood grain aluminum veneer: a new favorite of decoration that blends modernity and tradition

- Aluminum veneer customization, creating a new trend of personalized space

- Aluminum veneer customization, creating personalized spatial aesthetics

- Wood grain aluminum veneer, a fashionable choice for modern architecture

- Aluminum panel with a new look: Imitation wood grain aluminum veneer, the finishing touch of architectural art

Industry dynamics

- Exploring the charm of wood grain aluminum veneer: a fashionable choice for modern architecture!

- Hollow out fluorocarbon aluminum veneer is a lightweight and beautiful building material

- The history and development of aluminum veneer

- Imitation wood grain aluminum veneer: a perfect fusion of fashion and nature

- What are the effects of the thickness of the oxide film on aluminum veneer?

Frequently asked questions

- How to evaluate the impact of the plasticity of aluminum veneer on the appearance of buildings?

- Is the surface treatment method of aluminum veneer restricted?

- Will the thickness of aluminum veneer affect its service life?

- Can the insulation function of aluminum veneer improve the comfort of buildings?

- Can aluminum veneer be used for building platform design?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

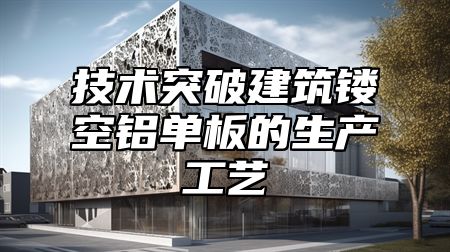

Technological breakthrough in the production process of hollow aluminum veneer in architecture

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: 2022-03-04 06:48:43

- Click:0

With the development of the construction industry,Aluminum veneerGradually becoming a favored building material. In the application process of aluminum veneer, architectural hollow aluminum veneer is a new type of product with innovative design. In order to meet market demand, the production process of hollow aluminum veneer in buildings has also made technological breakthroughs in recent years. The following will provide a detailed introduction from multiple aspects.

1、 Cutting process

Traditional architectural hollow aluminum veneer is produced through stamping and mold forming, which has low production efficiency and cannot achieve complex hollow design. With the continuous development of CNC cutting technology, it is now possible to produce hollow aluminum veneer for buildings using CNC cutting. Numerical control cutting has the characteristics of high precision and efficiency, which can realize the design of various complex shapes, and can perform multiple cuts as needed, thereby improving production efficiency and product quality.

2、 Surface treatment process

The surface of the hollow aluminum veneer in the building presents a unique hollow effect after special processing. The traditional surface treatment process is mainly achieved through spraying and electrophoresis, but these two methods have certain limitations and cannot meet the requirements of complex hollow design. With the continuous development of laser engraving technology, laser engraving can now be used to treat the surface of hollow aluminum veneers in buildings. Laser engraving has the characteristics of high precision, fast speed, and good effect. It can achieve the design of various complex shapes and can be engraved multiple times as needed, thereby improving the quality and effect of surface treatment.

3、 Welding process

The traditional architectural hollow aluminum veneer is connected to various components through welding, which poses certain safety hazards and quality issues. With the continuous development of laser welding technology, laser welding can now be used to connect hollow aluminum veneers in buildings. Laser welding has the characteristics of high precision, fast speed, and no pollution, which can achieve high-quality connections and avoid safety hazards and quality problems caused by welding.

4、 Painting process

The traditional architectural hollow aluminum veneer is coated by spraying, which has certain waste and environmental pollution problems. With the continuous development of water-based coating technology, water-based coatings can now be used to coat hollow aluminum veneers in buildings. Water based coatings have the characteristics of environmental protection, energy saving, and durability, which can reduce the amount of coating used and its impact on the environment, while also improving the product's service life and appearance.

The production process of hollow aluminum veneer in architecture has achieved technological breakthroughs, which not only improve production efficiency and product quality, but also reduce environmental pollution and resource waste. In the future development, with the continuous advancement of technology and the increasing awareness of environmental protection among people, it is believed that the production process of hollow aluminum veneer in buildings will achieve more technological breakthroughs and developments.

Customer service QQ

Customer service QQ