Industry information

Company News

- Customized aluminum veneer for a more tasteful home!

- Aluminum veneer: the new darling of fashion in the industry?

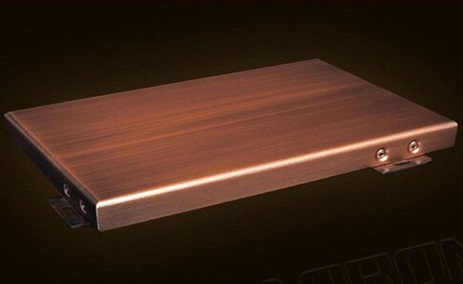

- Wood grain aluminum veneer: natural aesthetics in modern architecture

- Aluminum veneer has infinite charm, revealing the new favorite of modern architecture

- Wood grain aluminum veneer: the new darling of modern architecture, the perfect fusion of nature and technology

Industry dynamics

- Aluminum veneer customization, creating a new trend of personalized space

- Innovative design and technological breakthrough of 2.0mm hollow aluminum veneer

- Can aluminum veneer be used outdoors?

- Customized aluminum veneer: an artistic journey to create personalized spaces

- Aluminum veneer customization, creating your own personalized space

Frequently asked questions

- Can aluminum veneer be used for building platform design?

- Can the insulation function of aluminum veneer improve the comfort of buildings?

- How to evaluate the impact of the plasticity of aluminum veneer on the appearance of buildings?

- What are the limitations of the application scope of aluminum veneer?

- Can aluminum veneer be applied to the exterior design of high-rise buildings?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Design and construction techniques of perforated aluminum veneer for suspended ceilings

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: March 2, 2025 11:45:16

- Click:0

Ceiling perforationAluminum veneerIt is a common decorative material, with its unique perforated design and beautiful appearance, bringing people a more comfortable and beautiful living environment. The design and construction techniques of perforated aluminum veneer for suspended ceilings are also important factors affecting their decorative effect and service life. Below, we will provide a detailed introduction to the design and construction techniques of perforated aluminum veneer for suspended ceilings.

1、 Design and Skills

1. Accurate measurement: Before designing and constructing perforated aluminum veneers for suspended ceilings, it is necessary to accurately measure the size of the indoor ceiling to ensure that the selected perforated aluminum veneer for suspended ceilings is of appropriate size. When punching, it is also necessary to choose the appropriate punching method and size according to actual needs to achieve personalized and artistic effects.

2. Material selection: When selecting perforated aluminum veneer for suspended ceilings, consideration should be given to its strength and durability. High quality perforated aluminum veneer for suspended ceilings should be made of high-strength aluminum alloy materials with good strength and durability.

3. Punching treatment: Punching treatment of perforated aluminum veneer for ceiling is also one of the very important factors. When punching, attention should be paid to adjusting the direction and size of the punching to ensure aesthetics and ventilation. Also, it is important to avoid using hard objects to scratch the surface of aluminum veneer, which can cause scratches or damage.

4. Installation techniques: When installing perforated aluminum panels for suspended ceilings, the following points should be noted: ensuring the flatness and verticality of the perforated aluminum panels for suspended ceilings; Reasonably arrange the keel and accessories according to the design requirements; Pay attention to the position and angle of the fixed suspension rod to enhance the stability of the entire structure.

2、 Construction Techniques

1. Safety first: During the construction process of perforated aluminum veneer for suspended ceilings, it is important to pay attention to safety issues, such as using tools with caution and preventing electric shock.

2. Moisture proof treatment: Due to the presence of certain gaps on the surface of perforated aluminum veneer in the ceiling, it is easily affected by moisture. To prevent moisture, a waterproof layer can be added above the aluminum veneer or treated with a moisture-proof agent.

3. Regular inspection: During use, it is necessary to regularly inspect and maintain the perforated aluminum veneer of the ceiling to extend its service life and maintain its aesthetic appearance.

The design and construction techniques of perforated aluminum veneer for suspended ceilings have a significant impact on its decorative effect and service life. When designing and constructing perforated aluminum veneer for suspended ceilings, appropriate materials and processes should be selected according to the actual situation, and the operation procedures should be strictly followed to ensure its quality and safety.

Customer service QQ

Customer service QQ