Industry information

Company News

- Wood grain aluminum veneer: a perfect fusion of nature and fashion

- Exploring "Curtain Wall Aluminum Veneer": Innovative Password for Architectural Aesthetics

- Imitation Wood Grain Aluminum Veneer: Natural Charm in Modern Architecture

- Curtain wall aluminum veneer: creating the "golden decoration" of modern architectural art

- Imitation wood grain aluminum veneer: the fashionable new favorite of modern architecture

Industry dynamics

- How to reduce the purchase price of aluminum veneer?

- New favorite of aluminum plate: the fashionable evolution of imitation wood grain aluminum veneer

- The advantages of efficient and durable 1.5mm curved aluminum veneer

- Wood grain aluminum veneer, the new darling of modern architecture

- The application prospects of aluminum veneer for engineering walls in the field of construction

Frequently asked questions

- Can aluminum veneer be applied to the exterior design of high-rise buildings?

- Can the insulation function of aluminum veneer improve the comfort of buildings?

- Is the surface treatment method of aluminum veneer restricted?

- What are the types of aluminum veneer?

- Does the production of aluminum veneer require certification?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

The three elements of punching aluminum veneer processing: hole diameter, hole spacing, and punching rate

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: February 20, 2025 19:10:38

- Click:0

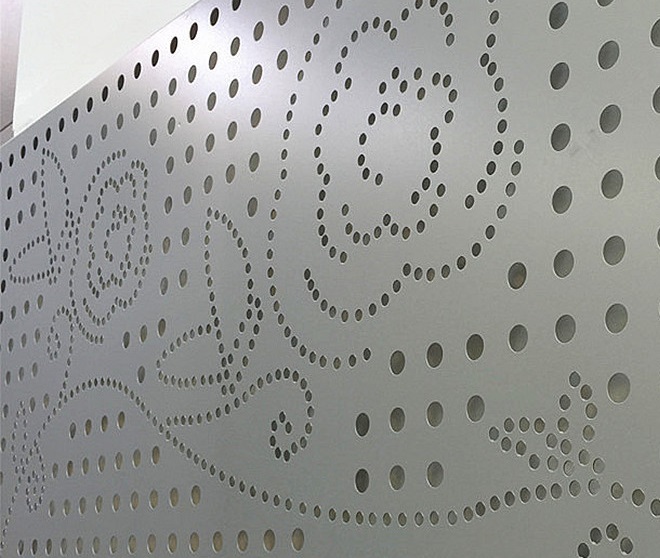

punchingAluminum veneerIt is a common building material with advantages such as light weight, high strength, corrosion resistance, sound insulation, etc. It is widely used in commercial buildings, residential buildings and other fields. When processing punched aluminum veneer, aperture, hole spacing, and punching rate are three very important factors that directly affect the quality and performance of punched aluminum veneer. Let's now provide a detailed introduction to these three elements.

Aperture refers to the size of the holes on punched aluminum veneer. The size of the aperture usually depends on factors such as the required ventilation and air permeability, as well as decorative effects. Generally speaking, the larger the aperture, the better the ventilation and air permeability, but the decorative effect may be affected to some extent. Reasonable aperture design should be carried out according to actual needs when processing punched aluminum veneer.

Hole spacing refers to the distance between two adjacent holes. The size of the hole spacing usually depends on factors such as the required acoustic effect and structural stability. Generally speaking, the larger the hole spacing, the better the acoustic effect, but the structural stability may be affected to some extent. Reasonable hole spacing design should be carried out according to actual needs when processing punched aluminum veneer.

Thirdly, punching rate refers to the proportion of holes on punched aluminum veneer. The size of the punching rate usually depends on factors such as the desired decorative effect and structural strength. Generally speaking, the higher the punching rate, the better the decorative effect, but the structural strength may be affected to some extent. When processing punched aluminum veneer, it is necessary to design a reasonable punching rate according to actual needs.

When processing punched aluminum veneer, aperture, hole spacing, and punching rate are three very important factors. They directly affect the quality and performance of punched aluminum veneer. When selecting processing parameters, it is necessary to design and adjust them reasonably according to actual needs to ensure that the selected parameters can meet one's own needs and budget requirements. During the processing, it is also necessary to strictly follow the relevant requirements to ensure the quality and safety of the product.

Customer service QQ

Customer service QQ