Industry information

Company News

- Aluminum veneer: the 'invisible hero' of modern architecture

- Imitation wood grain aluminum veneer: a blend of modern and traditional architectural aesthetics

- Wood grain aluminum veneer: a perfect fusion of nature and modernity

- Aluminum veneer customization, creating the art of personalized space

- Aluminum veneer customization, creating the art of personalized space

Industry dynamics

- High quality 2.5mm aluminum veneer brushed panel showcases noble taste

- Aluminum veneer: The beauty of architecture lies within this single piece of metal

- Imitation wood grain aluminum veneer: a perfect encounter between modernity and nature

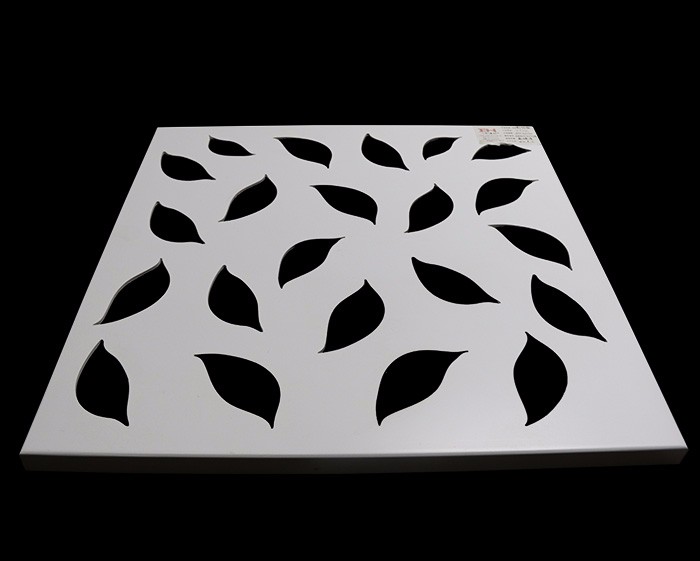

- Hollow out fluorocarbon aluminum veneer is a lightweight and beautiful building material

- Imitation wood grain aluminum veneer: a new favorite of modern and traditional decoration blending

Frequently asked questions

- Can the insulation function of aluminum veneer improve the comfort of buildings?

- Will the thickness of aluminum veneer affect its service life?

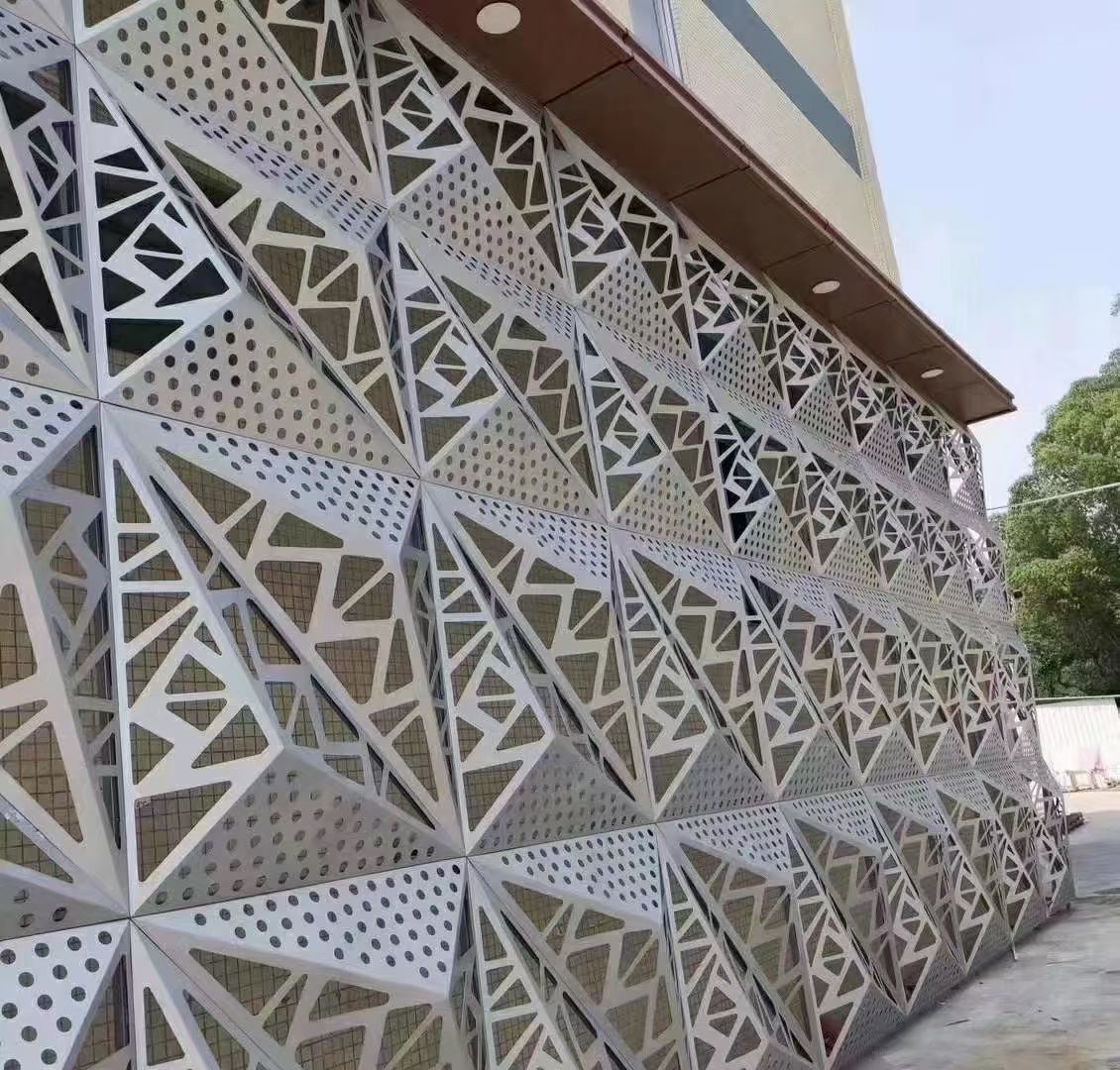

- Can aluminum veneer be applied to the exterior design of high-rise buildings?

- What are the types of aluminum veneer?

- How to evaluate the impact of the plasticity of aluminum veneer on the appearance of buildings?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Selection guide for 2.5mm thick aluminum veneer

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: 2022-03-14 17:24:46

- Click:0

Aluminum veneerIt is a lightweight, weather resistant, fire-resistant, and corrosion-resistant building material that has a wide range of applications in architectural decoration. And 2.5mm thick aluminum veneer is a common specification with high strength and stability. When selecting 2.5mm thick aluminum veneer, the following aspects should be noted:

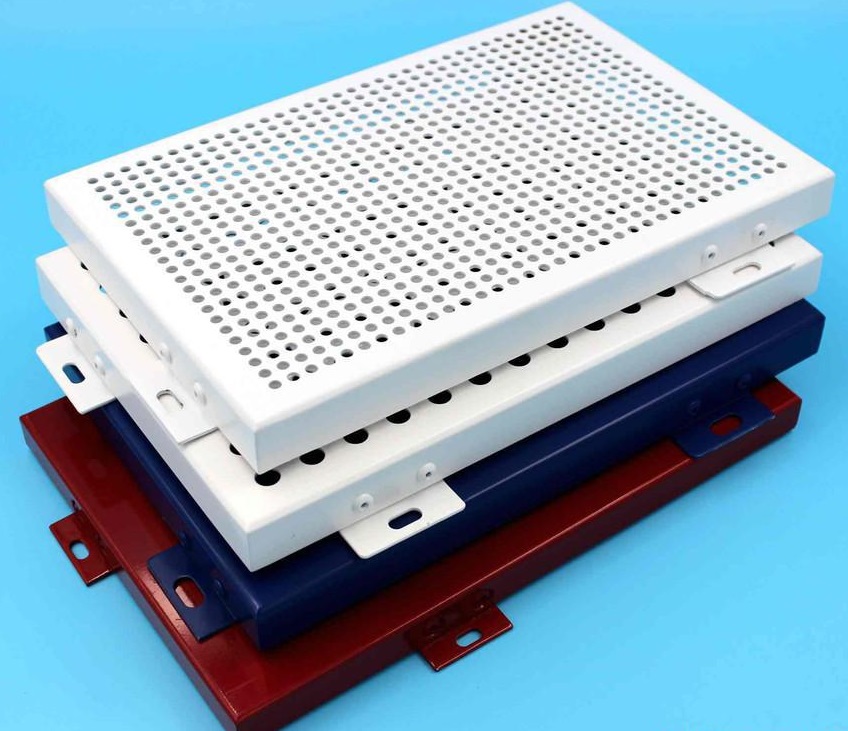

1、 Material

The material of aluminum veneer is one of the important factors affecting its performance and quality. Generally speaking, high-quality aluminum veneer should be made of high-strength and corrosion-resistant aluminum alloy materials, and the surface should be treated with anodizing or spraying to improve its durability and aesthetics. When selecting 2.5mm thick aluminum veneer, it is necessary to choose products produced by reputable manufacturers and carefully inspect their materials and surface treatment methods.

2、 Specifications

The specification of 2.5mm thick aluminum veneer is also one of the factors to consider when purchasing. Aluminum veneer of different specifications is suitable for different occasions and building structures, so it needs to be selected according to actual needs. Generally speaking, 2.5mm thick aluminum veneer can be divided into various widths and lengths, such as 1000mm wide, 2400mm long, etc., which need to be selected according to specific usage scenarios.

3、 Surface treatment method

The surface treatment method of aluminum veneer is also one of the important factors affecting its service life and appearance. The common surface treatment methods on the market currently include anodizing, spraying, electrophoretic coating, etc. Anodizing treatment can form a hard oxide film on the surface of aluminum veneer, thereby improving its wear resistance and corrosion resistance; The spray treatment method can form a uniform coating on the surface of aluminum veneer, thereby improving its aesthetics and corrosion resistance. When selecting 2.5mm thick aluminum veneer, it is necessary to choose the appropriate surface treatment method according to the specific usage environment and requirements.

4、 Manufacturer reputation

When selecting 2.5mm thick aluminum veneer, it is also necessary to consider the manufacturer's reputation and after-sales service. High quality manufacturers should have complete production equipment and technical teams, able to provide high-quality products and comprehensive after-sales service. When making a purchase, it is necessary to choose a manufacturer with a good reputation and credibility, and understand their after-sales service policies and guarantee measures.

When selecting 2.5mm thick aluminum veneer, it is necessary to comprehensively consider factors such as material, specifications, surface treatment methods, and manufacturer reputation to ensure that the selected product meets actual needs and standard requirements. We also need to pay attention to product quality and service guarantee to ensure the overall quality and stability of the decorative effect.

Customer service QQ

Customer service QQ