Industry information

Company News

- Aluminum veneer curtain wall, the fashionable outerwear of modern architecture

- Wood grain aluminum veneer: a unique natural beauty in modern architecture

- Imitation wood grain aluminum veneer: a fashionable choice for modern architecture

- Wood grain aluminum veneer, the fashionable new favorite of modern architecture

- Personalized aluminum veneer, customize your space style

Industry dynamics

- Aluminum veneer curtain wall: the fashionable coat of modern architecture

- How can aluminum veneer improve production efficiency?

- Wood grain aluminum veneer: a perfect fusion of nature and technology

- Installation skills of aluminum veneer for exterior wall ceiling

- Multiple colors to choose from, decorative effect of 1.5mm curved aluminum veneer

Frequently asked questions

- Can the insulation function of aluminum veneer improve the comfort of buildings?

- How to evaluate the impact of the plasticity of aluminum veneer on the appearance of buildings?

- What are the types of aluminum veneer?

- How does aluminum veneer provide the wind resistance required for modern buildings?

- Can aluminum veneer be used for building platform design?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

The reasons for the quality problems of fluorocarbon aluminum veneer

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: February 27, 2025 06:51:43

- Click:0

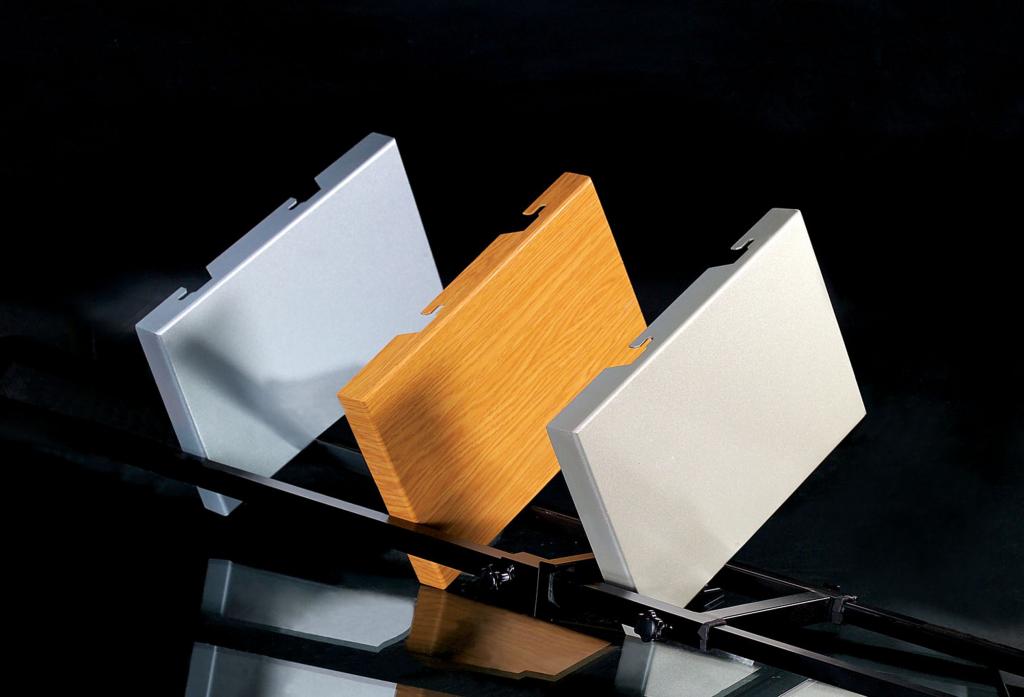

FluorocarbonAluminum veneerIt is a widely used building decoration material with advantages such as good weather resistance, strong anti-corrosion performance, and good decorative effect. During use, fluorocarbon aluminum veneer may also encounter some quality issues, which are often related to the following reasons.

1. Quality issues with raw materials

The quality of fluorocarbon aluminum veneer first depends on the quality of its raw materials. If there are impurities or impure substances in the raw materials, it will cause problems such as color difference and porosity on the surface of fluorocarbon aluminum veneer. The strength and hardness of raw materials also affect the service life and compressive performance of fluorocarbon aluminum veneer.

1. Production process issues

The production process of fluorocarbon aluminum veneer also has a significant impact on its quality. If the production process is not standardized or the operation is improper, it will lead to scratches, unevenness and bumps on the surface of fluorocarbon aluminum veneer. During the spraying process, if the pressure of the spray gun is uneven or the spraying distance is improper, it can also cause color difference and uneven coating thickness on the surface of fluorocarbon aluminum veneer.

1. Storage and transportation issues

Fluorocarbon aluminum veneer also requires special attention during storage and transportation. If the storage environment humidity is too high or the temperature is too low, it will cause problems such as watermarks and oxidation on the surface of fluorocarbon aluminum veneer. During transportation, if subjected to compression or collision, it can also cause deformation, cracks, and other issues on the surface of fluorocarbon aluminum veneer.

1. Maintenance and upkeep issues

Fluorocarbon aluminum veneer also requires regular maintenance during use. If not cleaned and maintained in a timely manner, it can lead to problems such as dirt and dust on the surface of fluorocarbon aluminum veneer. During use, excessive force or tools can also cause scratches, damage, and other issues on the surface of fluorocarbon aluminum veneer.

The quality problems of fluorocarbon aluminum veneer are often related to multiple factors such as raw material quality, production process, storage and transportation, and maintenance. When using fluorocarbon aluminum veneer, attention should be paid to selecting high-quality raw materials, standardized production processes, appropriate storage and transportation methods, and regular maintenance measures to ensure the quality and service life of fluorocarbon aluminum veneer.

Customer service QQ

Customer service QQ