Industry information

Company News

- 2. Customized aluminum veneer, personalized design, making your home look brand new! 3. Aluminum veneer customization

- Wood grain aluminum veneer: retro sentiment of modern building materials

- Aluminum veneer customization: the secret weapon for creating personalized spaces

- Wood grain aluminum veneer, the green poetry of modern architecture

- Aluminum veneer customization, creating the beauty of exclusive space!

Industry dynamics

- Analysis and Research Report on the Market Dynamics of Aluminum Veneer Prices

- Aluminum veneer: not just a building material, but also a fusion of art and technology

- Advantages and disadvantages of painted ceiling aluminum veneer

- Customized aluminum veneer, making the space look brand new!

- Aluminum veneer customization, creating a new trend of personalized space

Frequently asked questions

- What are the types of aluminum veneer?

- How to evaluate the impact of the plasticity of aluminum veneer on the appearance of buildings?

- How does aluminum veneer provide the wind resistance required for modern buildings?

- What are the limitations of the application scope of aluminum veneer?

- Can aluminum veneer be used for building platform design?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Production process and technical analysis of hyperbolic punched aluminum veneer

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: February 22, 2025 16:35:38

- Click:0

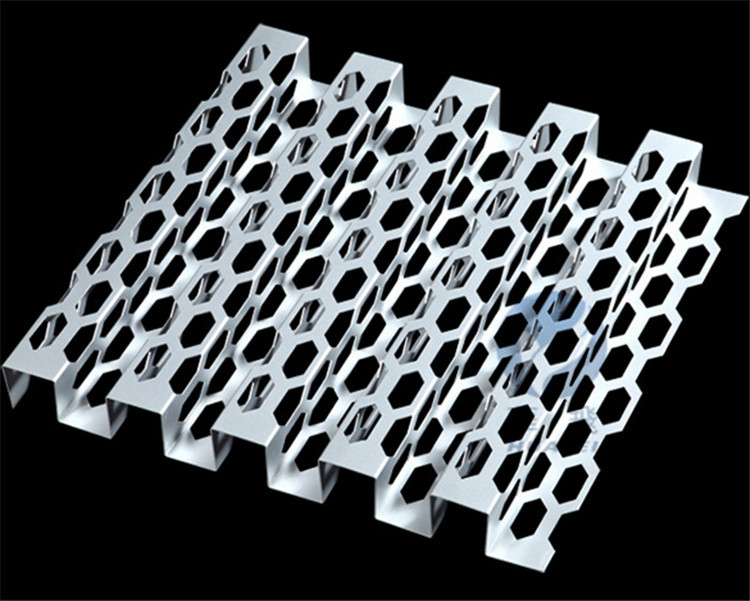

Hyperbolic punchingAluminum veneerIt is a new type of building decoration material with unique shape and good decorative effect. Its production process is relatively complex and requires multiple steps to complete. This article will provide a detailed introduction to the production process and technical analysis of hyperbolic punched aluminum veneer.

1、 Production process

1. Raw material preparation

The main material of hyperbolic punched aluminum veneer is aluminum alloy plate, which requires processing such as cutting, bending, and punching. In the process of preparing raw materials, it is necessary to pay attention to the quality and specifications of the materials to ensure that they meet the design requirements.

2. Mold making

Produce corresponding molds according to the requirements of the design drawings. The quality of the mold directly affects the dimensional accuracy and surface quality of the final product. High precision processing equipment and techniques are required when making molds to ensure the accuracy and reliability of the molds.

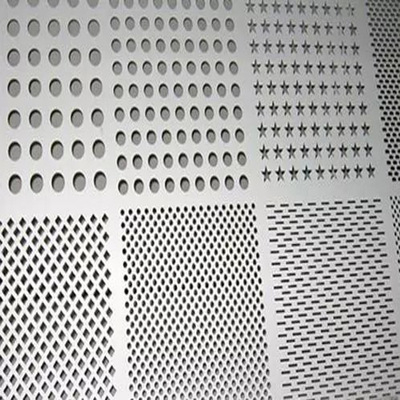

3. Punching processing

Place the aluminum alloy plate into the mold and perform punching processing through a stamping machine. The size and shape of the punching can be adjusted according to design requirements. After the punching process is completed, remove the aluminum alloy plate from the mold.

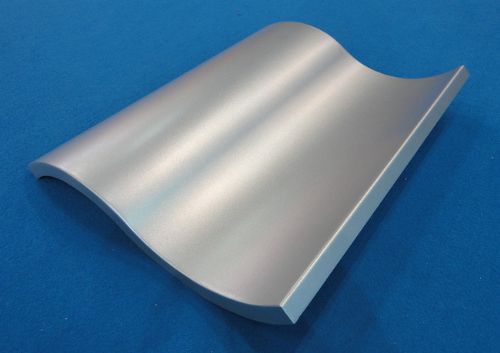

4. Bending forming

Bend the punched aluminum alloy plate into the desired hyperbolic shape. Bending molding requires the use of professional bending machines and processes to ensure product quality and stability.

5. Surface treatment

Surface treatment of hyperbolic punched aluminum veneer, including anodizing, electrophoretic coating, etc. These processing methods can improve the hardness and wear resistance of aluminum veneer, while also increasing its aesthetics and texture.

6. Welding assembly

After surface treatment, it is necessary to weld and assemble the hyperbolic punched aluminum veneer. Common welding methods include spot welding, seam welding, etc. Aluminum veneer can be assembled into a whole through welding, ensuring the strength and sealing of its connections.

2、 Technical analysis

1. Mold making technology

Mold making is one of the important processes in the production of hyperbolic punched aluminum veneer. The quality of the mold directly affects the dimensional accuracy and surface quality of the final product. High precision processing equipment and techniques are required when making molds to ensure the accuracy and reliability of the molds. The commonly used mold making processes include CNC machining, electrical discharge machining, etc.

2. Punching processing technology

Punching processing is one of the key processes in the production of hyperbolic punched aluminum veneer. The size and shape of the punching can be adjusted according to design requirements. The commonly used punching machines include hydraulic punching machines, mechanical punching machines, etc. During the punching process, attention should be paid to controlling the magnitude and direction of the force to avoid damaging the surface of the aluminum veneer or causing cracks.

3. Bending forming technology

Bending forming is one of the important processes in the production of hyperbolic punched aluminum veneer. Bending molding requires the use of professional bending machines and processes to ensure product quality and stability. The commonly used bending machines include CNC bending machines, hydraulic bending machines, etc. During the bending process, it is necessary to pay attention to controlling the force and speed to avoid problems such as cracking or deformation.

Hyperbolic punched aluminum veneer, as a new type of building decoration material, has a unique shape and good decorative effect. Its production process is relatively complex and requires multiple steps to complete. However, through continuous technological innovation and improvement, we believe that the future hyperbolic punched aluminum veneer will more perfectly meet people's needs for architectural decoration.

Customer service QQ

Customer service QQ