Industry information

Company News

- Wood grain aluminum veneer, natural charm in industrial style

- Imitation wood grain aluminum veneer: retro style of modern architecture

- Aluminum veneer: the 'invisible star' in modern architecture

- Customized aluminum veneer, creating a new trend of personalized space

- Aluminum veneer: the 'invisible hero' in architecture

Industry dynamics

- Have you noticed that many buildings have 'silver coats' on their exterior walls? This is not

- Imitation wood grain aluminum veneer: a green choice for modern architecture

- Imitation wood grain aluminum veneer: the new favorite of modern architecture, the perfect integration of nature and technology

- Wood grain aluminum veneer, the fashionable choice for modern architecture?

- Installation and maintenance methods of wood grain aluminum veneer for curtain wall

Frequently asked questions

- Is the surface treatment method of aluminum veneer restricted?

- Does the production of aluminum veneer require certification?

- Can the insulation function of aluminum veneer improve the comfort of buildings?

- What are the limitations of the application scope of aluminum veneer?

- Can aluminum veneer be applied to the exterior design of high-rise buildings?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

How to choose high-quality aluminum veneer?

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: March 21, 2025 00:00:02

- Click:0

Aluminum veneerIt is a material widely used in fields such as construction and decoration, and its lightweight, high strength, and corrosion resistance are highly favored. How to choose high-quality aluminum veneer is a problem faced by many people. This article will provide a detailed introduction on how to choose high-quality aluminum veneer.

1. Material and thickness

The material and thickness of aluminum veneer are important factors affecting its quality. High quality aluminum veneer should be made of high-quality aluminum alloy materials with high strength and hardness, and the thickness should also meet actual needs. Generally speaking, aluminum veneers with a thickness between 0.8-1.2 millimeters can meet the needs of general building decoration.

1. Surface treatment

The surface treatment of aluminum veneer is also an important factor affecting its quality. High quality aluminum veneer should undergo surface treatment processes such as anodizing to form a dense oxide film on its surface, thereby improving its corrosion resistance and wear resistance. Surface treatment can also achieve different decorative effects through spraying, laminating, and other methods.

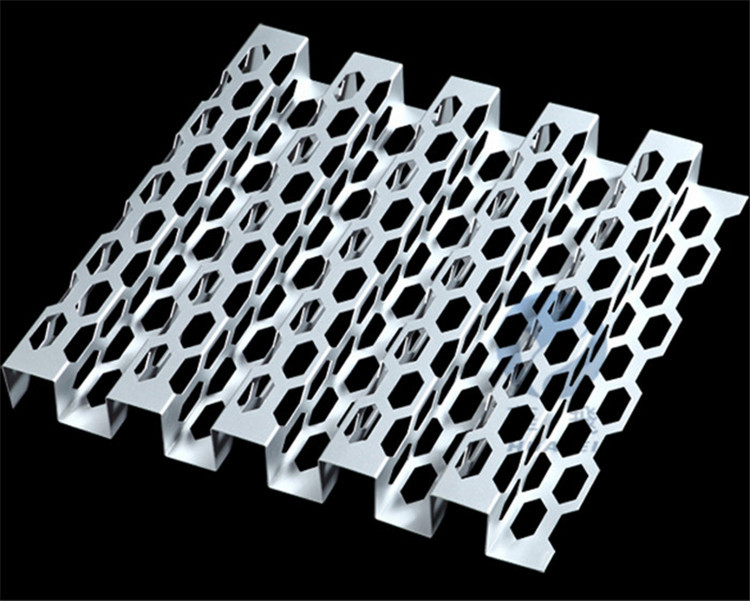

1. Processing technology

The processing technology of aluminum veneer is also an important factor affecting its quality. High quality aluminum veneer should be produced using advanced CNC machining equipment to ensure its dimensional accuracy and flatness. During the processing, attention should also be paid to avoiding scratches, deformations, and other issues to ensure the quality of the aluminum veneer.

1. Manufacturer's reputation

Choosing reputable manufacturers to purchase aluminum veneer is also an important measure to ensure its quality. The credibility of a manufacturer can be judged by understanding their production qualifications, production processes, after-sales service, and other aspects. You can also refer to the reviews and feedback of other users to obtain more information and suggestions.

Choosing high-quality aluminum veneer requires consideration of multiple aspects, including material and thickness, surface treatment, processing technology, and manufacturer reputation. Only by considering these factors comprehensively can we choose high-quality aluminum veneer products that truly meet our needs.

Customer service QQ

Customer service QQ